Share

The OnGuard Smart is a monitoring device that provides users with real-time data on the air quality in their spaces. Companies with vital manufacturing processes that create a corrosive environment, such as pulp and paper or petrochemical plants can benefit from integrating corrosion monitoring devices in their spaces. Additionally, companies with sensitive electronic equipment, like Data Centers, can benefit from continuous air monitoring to avoid unexpected breakdowns and ensure manufacturer warranty compliance. The OnGuard Smart helps companies keep an eye on corrosion levels and gauge how at risk of corrosion related failure their equipment is. Having this knowledge gives facilities the tools they need to determine next steps and decide if a new corrective solution is needed.

Installing an OnGuard Smart in your facility can help you keep track of your air quality in real-time and determine the source of corrosion before major damage occurs — avoiding unexpected downtime and costly repairs. Here are 5 reasons why using Purafil’s OnGuard Smart is a great corrosion monitoring solution.

1) Free Detailed Air Quality Reports Available Remotely

Each OnGuard Smart provides a 100% free, detailed, and ongoing air quality report. This report includes data and charts outlining changes in pressure, temperature, and corrosion levels as they occur.

Access this data however works best for you. The OnGuard has a built in LCD screen which provides an overview of data in real time, making it easy to quickly gauge where temperature, humidity and ISA environmental classification currently stands. More detailed reports can be viewed live on your web browser, or through the connection to an existing distributed control system (DCS) or a building management system (BMS).

2) Real-Time Readings

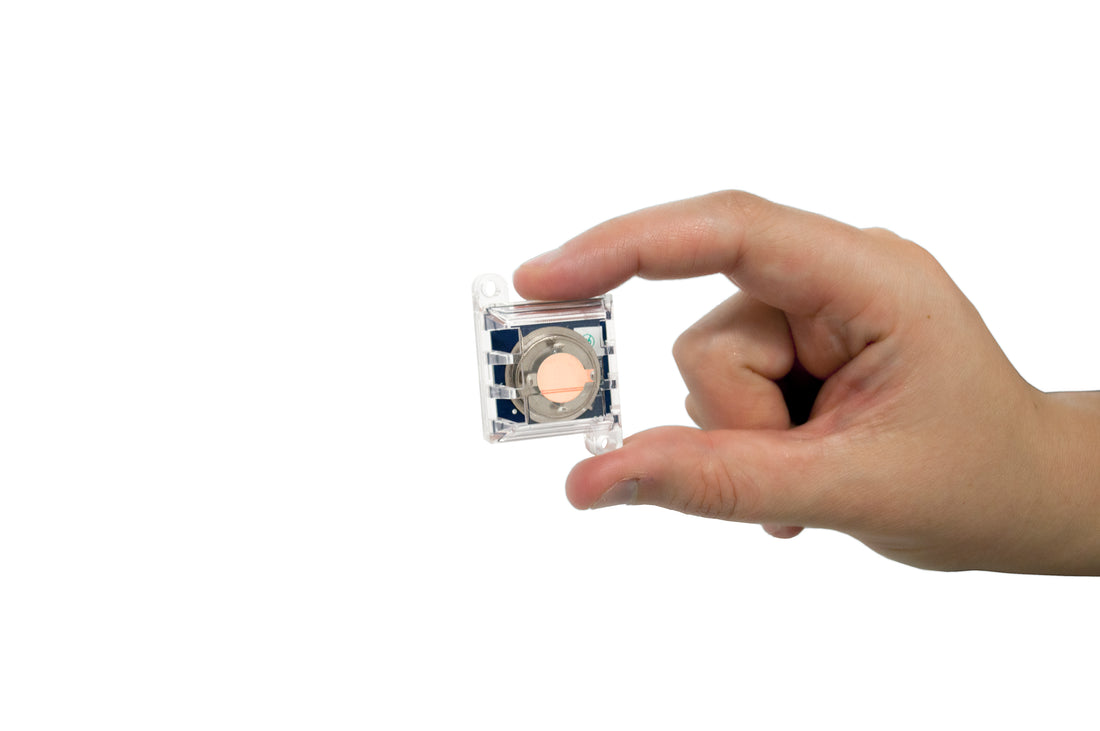

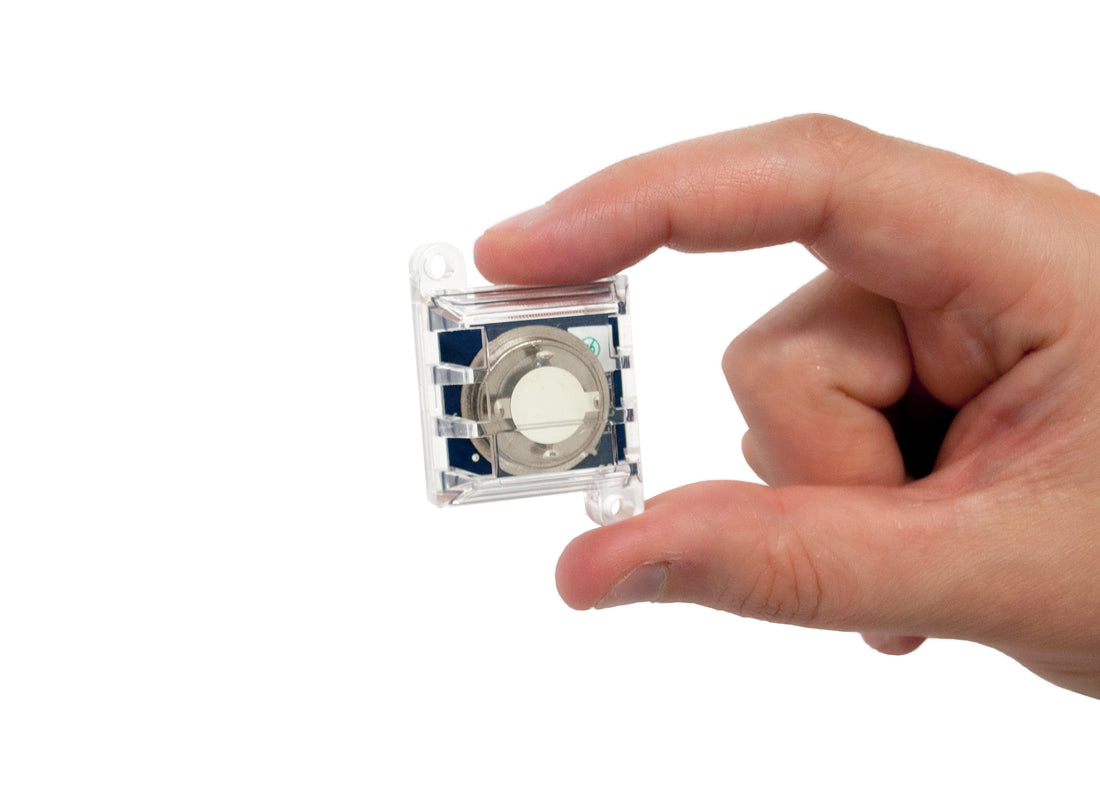

This corrosion monitoring device utilizes quartz crystal microbalance sensors that are copper and silver plated. These copper and silver metals are representative of the innerworkings of sensitive electronic equipment in your facilities, giving insight into how the air quality may be effecting actual equipment.

Through this device, corrosion rate, room air pressure, temperature and relative humidity is measured in real-time. This allows you to track peaks to help determine the sources of these spikes, and study corrosion data incrementally or cumulatively to determine trends overtime. The OnGuard Smart offers a glimpse into the status of your facilities air quality as the device logs all this information in real-time.

All readings correspond with the ISA Standard 71.04-2013 standard, ensuring you are receiving actionable, industry standard results. Measurements provided by the OnGuard Smart are accurate within ± 1% of full span.

3) Easy Setup and Low Maintenance

The OnGuard Smart unit features a small and compact design, weighing 255 grams and measuring 9x14x4.5cm in size. Its compact design makes it an easy to install and unobtrusive addition to even the busiest of facilities. We have also provided a quick start tutorial that helps make set up a breeze.

During installation, there are multiple ways to connect the device. One way is by connecting to existing process control systems with a 4-240mA connection. Additionally, the monitoring device can connect to a local or remote PC or Mac by using a local area network ethernet connection.

OnGuard Smart features low maintenance operations, and a long service life. The integrated sensors are reliable until they reach 4000 Angstroms of cumulative corrosion. For reference, based on ISA Standards, a severe, GX rating begins at anything over 2000 angstroms.

4) Sound the Alarm With Email Alerts

Receive email alerts anytime, anywhere with the OnGuard Smart Monitor. Users can set up email alerts for notification once certain data thresholds are met in their facilities which allows for quick intervention once a potentially damaging environment occurs. These alerts can be set up for a number of factors such as temperature, relative humidity, air pressure and corrosion levels. You can determine the high, low and rate-of-change limits for each variable. When these thresholds are met or are found to have been exceeded, you can trigger email alerts to be sent to a dedicated email address.

5) Peace of Mind

Having a device that provides insight into the facility’s air quality and corrosion levels is a great addition to any corrosion mitigation plan to monitor an ongoing or suspected problem. Even after a corrosion solution is put into place, an OnGuard monitor will help verify that it is operating at maximum efficiency and alert you if corrosion returns. Companies will receive accurate scientific data and can view patterns and trends over time, with ISA Standard 71.04-2013 results.

Knowledge is power. Understanding your spaces air quality is necessary in determining which corrosion mitigation solutions is right for you and having those numbers in real-time can help determine what the source of your new corrosion problem is. Additionally, Purafil’s team of Corrosion Control Experts can provide you any support and guidance you need along the way, even helping you create a tailored solution for your needs.

Installing a corrosion monitoring device is the next best step towards more efficient corrosion monitoring in a facility, and OnGuard Smart could be a great addition to your strategy. Buy an OnGuard Smart now or speak to an expert today to find out how corrosion monitoring technologies like this can benefit your company in the short-term and long run.

0 comment