Corrosion Coupon

- Unobtrusive, easy installation and data gathering

- Economical investment for determining air quality

- Scientifically supported, reliable results

- Provides the documentation required for manufacturers’ warranty compliance

- Vital for determining corrective solutions to protect equipment, processes, and artifacts

- Plus, enjoy the benefits of Purafil's digital coupon portal experience

Ships within 7 business days (Orders of 50 or more will ship within 4 weeks)

Couldn't load pickup availability

1 coupon per air vent for critical spaces

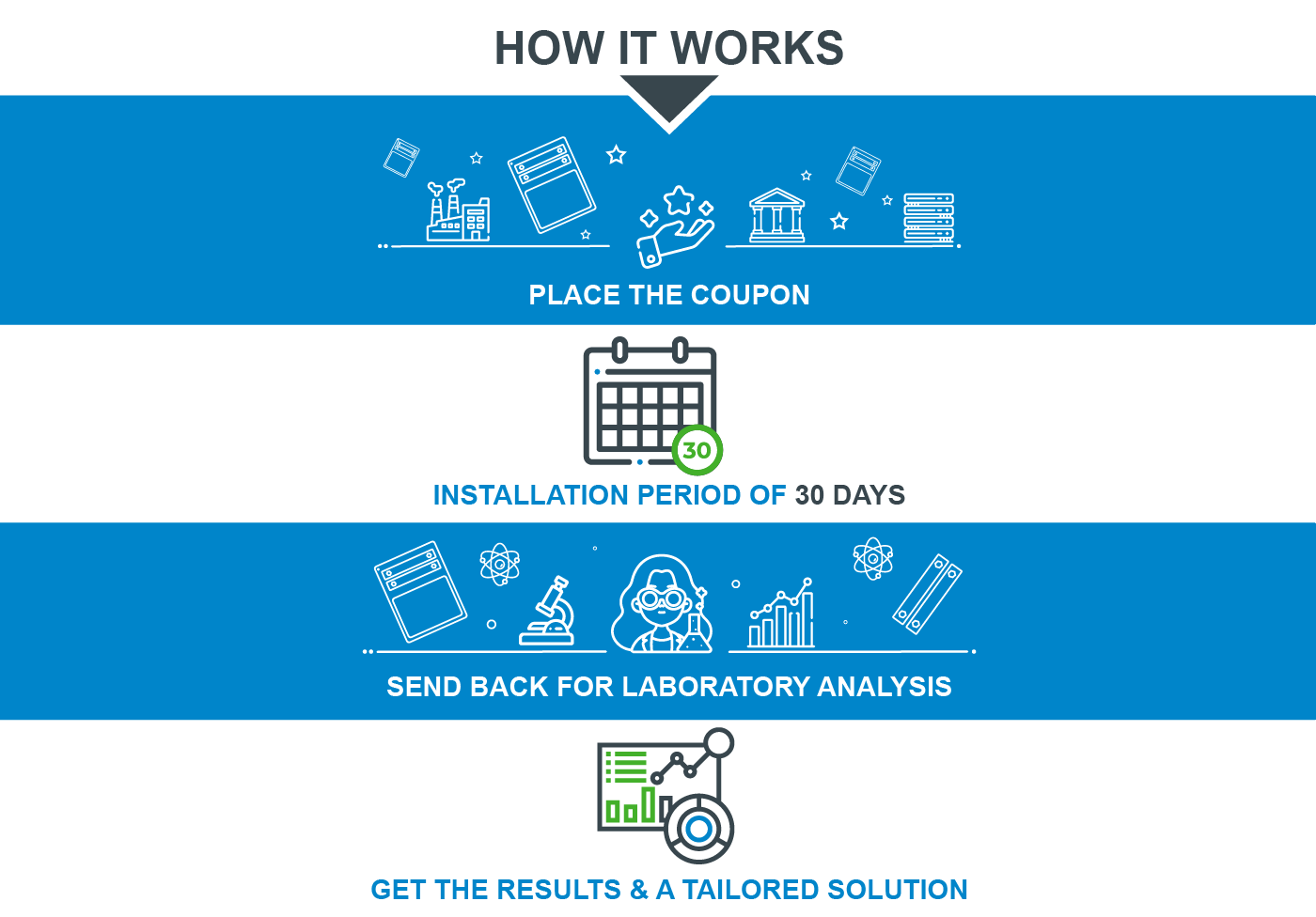

CORROSION DIAGNOSIS OVER A 30-DAY TIME PERIOD

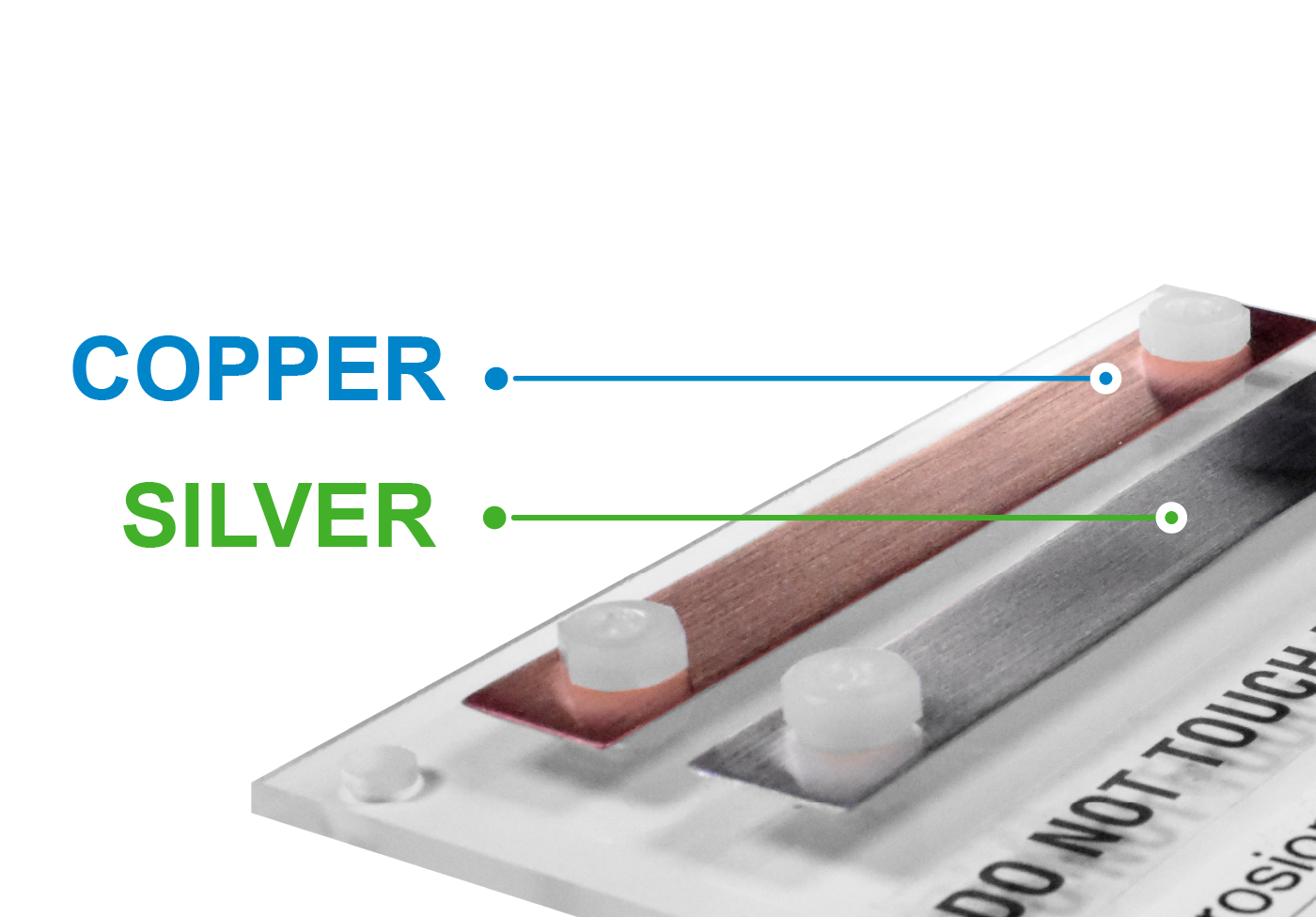

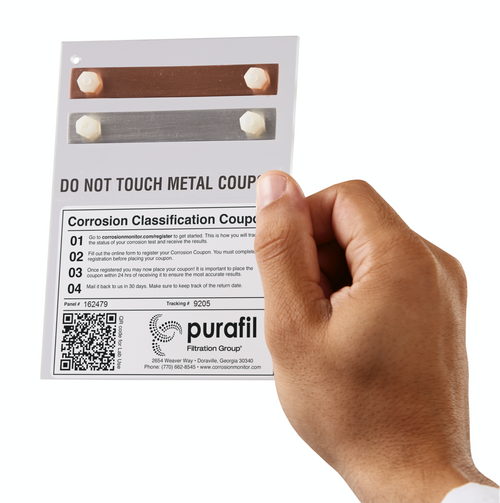

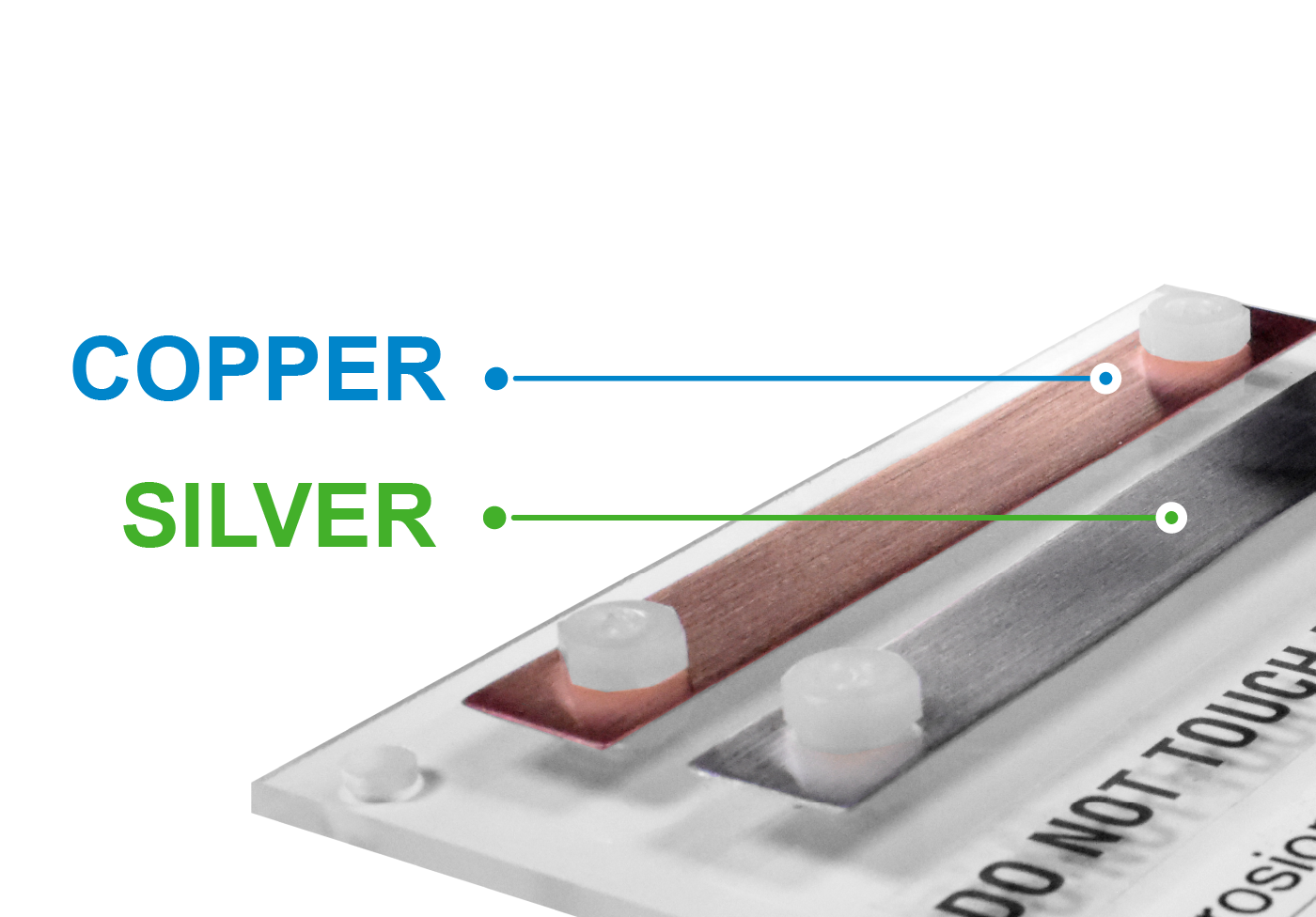

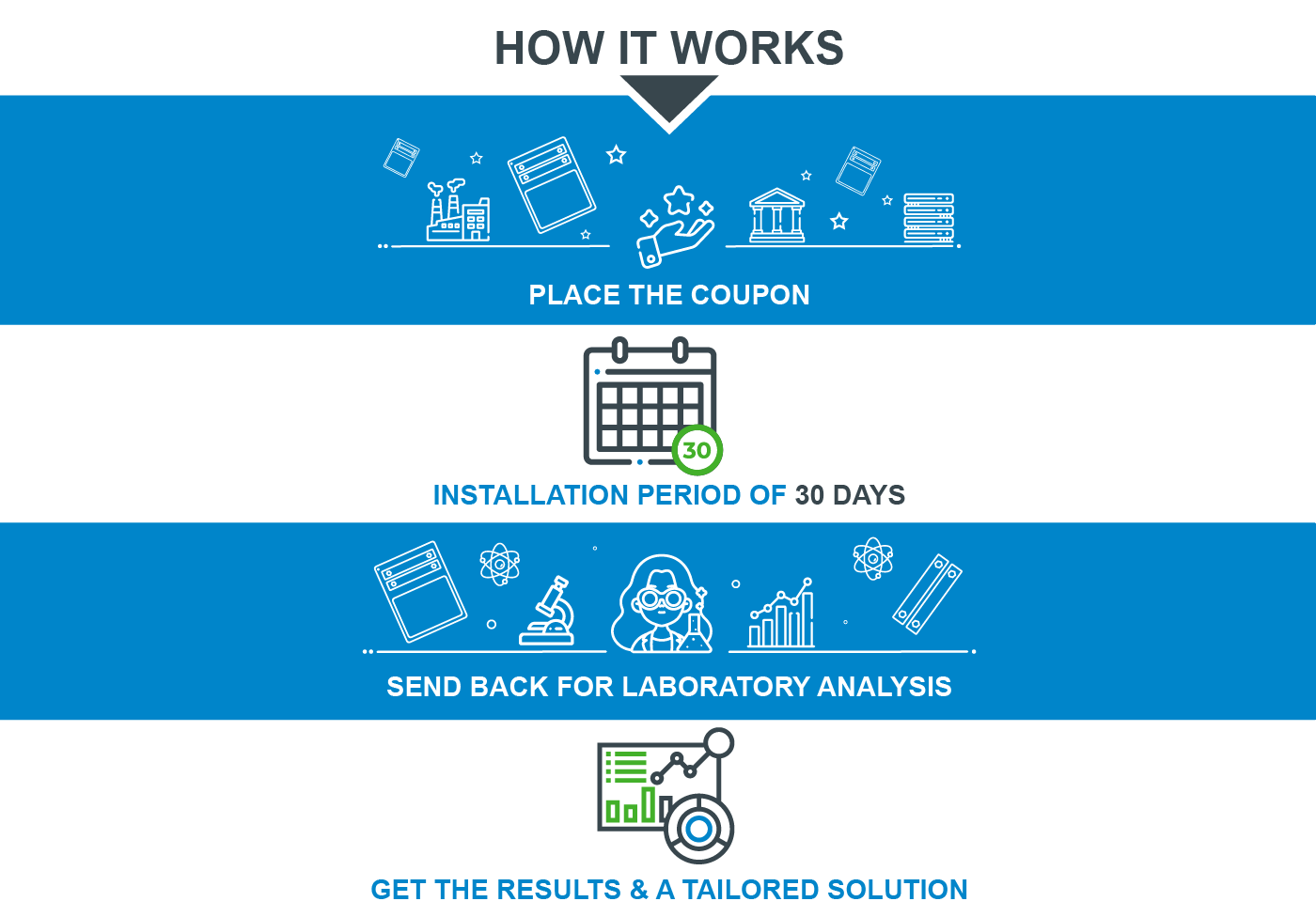

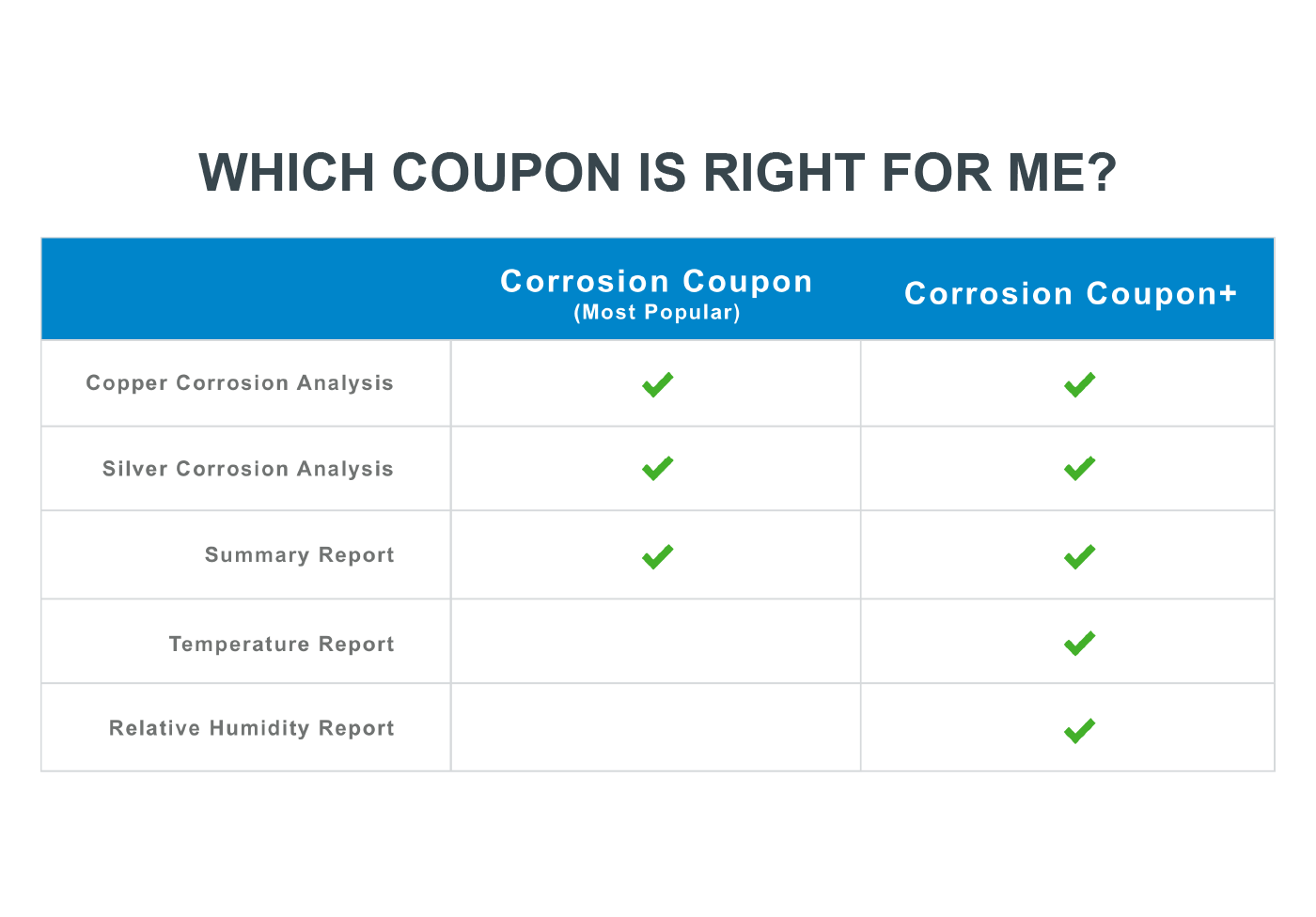

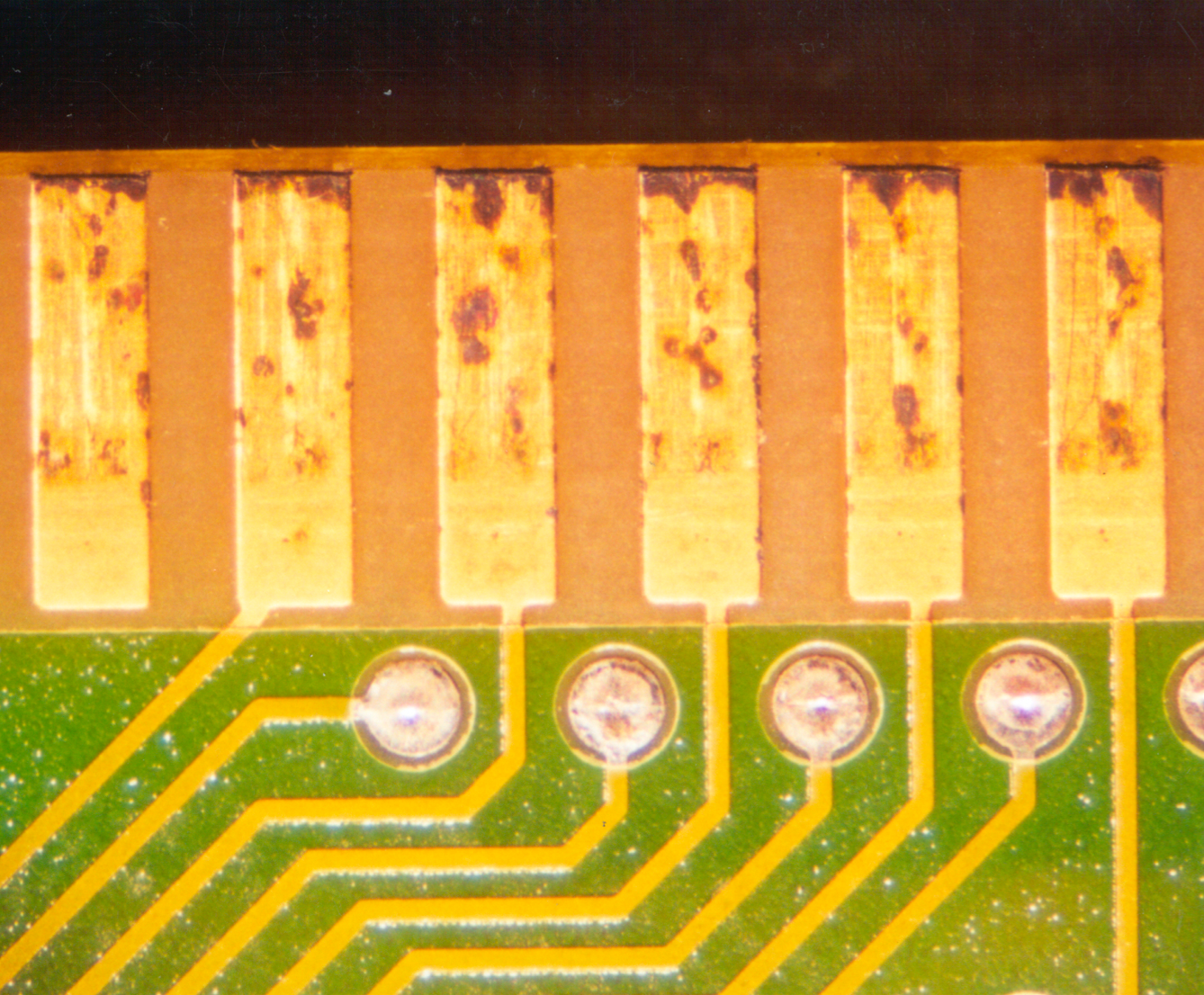

Corrosion Coupons have copper and silver metal strips. These metals represent the sensitive electronic components you rely on when exposed to the air in your environment. Over the course of a 30-day installation period, any corrosive air present will cause build up on the surface of these metal strips. After 30 days, the coupon is sent back to our lab for analysis where our scientists work to determine the air quality classification of the environment. You will receive a detailed report and a results-based solution to help determine next steps.

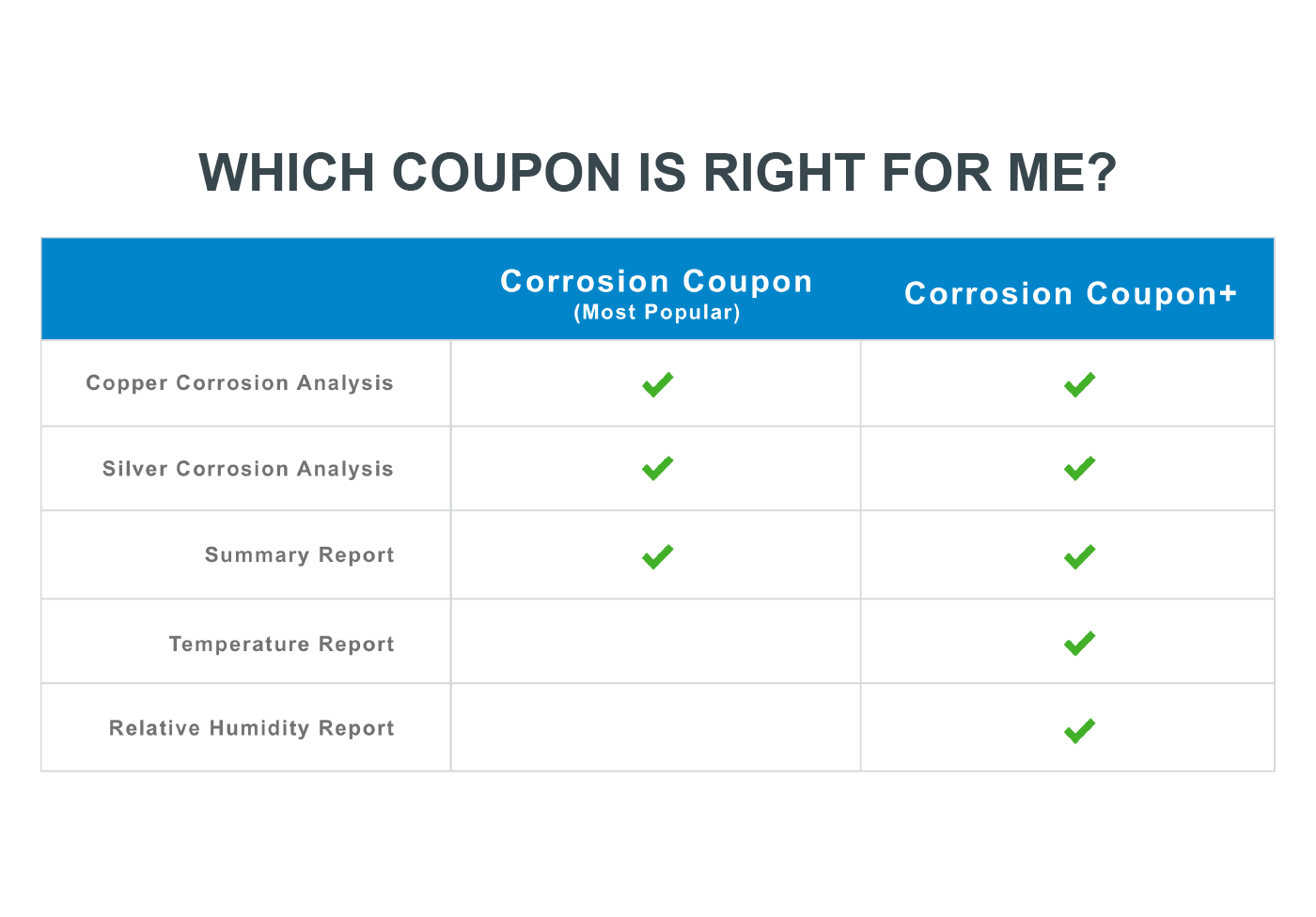

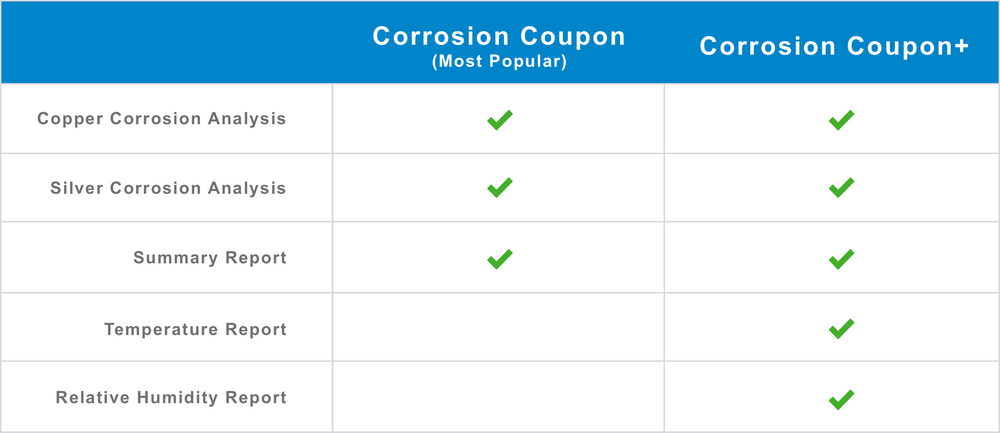

Additionally, the Corrosion Coupon+ contains a temperature and relative humidity logger for evaluation of controls and limits. Temperature should be maintained consistent with electronic equipment warranty requirements or at the lowest level possible consistent with personal comfort, typically 72°F, 22°C (±2°F, ±1-2°C). Relative Humidity should be less than 50% with close control of deviations, no greater than 6% per hour.

Since installing the complete Purafil solution, electronics failure has been eliminated, and they continue to maintain an G1 environment as classified by the International Society of Automation (ISA) Standard 71.04-2013 “Environmental Equipment Conditions for Process Management and Control Systems: Airborne Contaminants” - India’s Largest Telecom Company

Since utilizing Purafil, this critical control room has maintained a corrosion free environment for over 10 consecutive years. - A Major Paperboard Manufacturer

Purafil was selected because of their experience in the industrial marketplace and superior performance of their air purification systems. Purafil provided the technical knowledge and equipment necessary to build controlled environments that would protect production processes, and meet the standards established by the International Society of Automation (ISA). - World’s Largest Refinery

"Together, we developed an environmental control system that now works behind the scenes, protecting Michelangelo’s delicate work for future generations." - Representative, Preserving the Masterpiece in the Sistine Chapel

CORROSION CONTROL

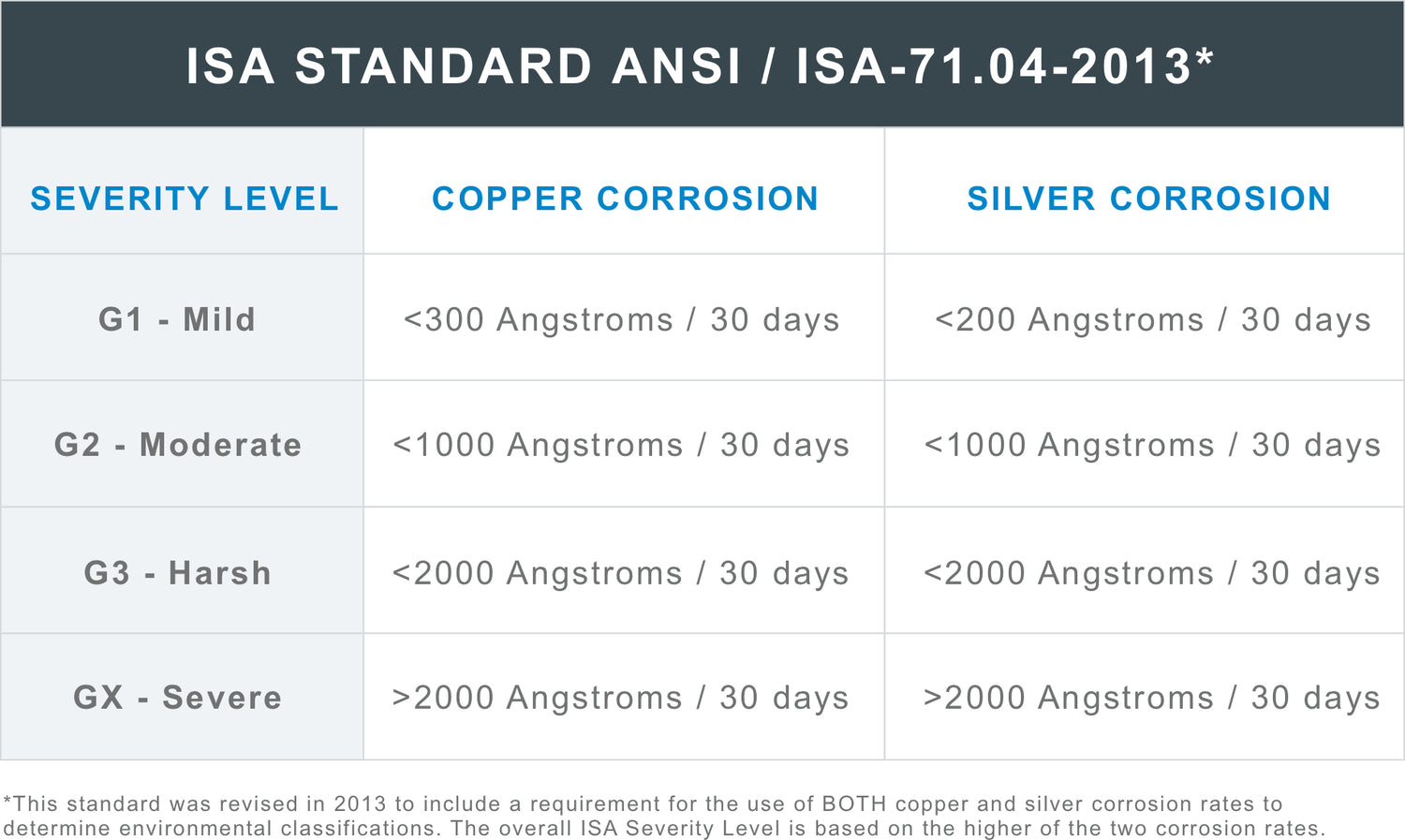

ISA ENVIRONMENTAL CLASSES:

AIRBORNE CONTAMINANTS

This standard requires that rooms containing backplane wired equipment, instrumentation, process control systems or computers, must have a G1 environmental classification, defined in terms of corrosion thickness as 0-299 Angstroms (Å) per 30 days on copper and 0-199 Å per 30 days on silver coupons. Purafil provides a report that directly correlates to the G1, G2, G3, and GX ratings.

COMMON INSTALLATION SITES

BENEFITS

Unobtrusive, easy installation & data gathering

Economical investment for determining air quality

Scientifically supported, reliable results

Provides the documentation required for manufacturers’ warranty compliance

Vital for determining corrective solutions to protect equipment, processes, and artifacts