Sign up below for a consultation to learn how corrosive air could be negatively impacting the data center facilities you service.

Schedule a Free Consultation with a Corrosion Control Expert

Don’t Get Left Behind: Reactivity Monitoring is Now an Industry Standard for Data Center Construction

Monitoring the air quality within a data center is no longer an option, it’s a necessity for the day-to-day operation of the facilities. A number of factors such as high levels of air pollution and airborne corrosive contaminants could lead to the failure of mission critical electronic equipment and facility downtime if left unchecked. On average, it costs $300K an hour anytime a data center experiences downtime in their facilities. This breaks down to $5,600 lost per minute. Don’t get left behind with outdated services, speak to one of Purafil’s Corrosion Control Experts today to learn how you can protect Data Centers from this invisible threat.

Data Centers Turn to Purafil for Reactivity Monitoring

IBM ENLISTS PURAFIL

IBM uses data centers all over the world to store and process data for its customers, making them incredibly valuable to the business. A server testing lab even tests every single server that IBM builds for three to six months to ensure that they won’t fail in real-world applications. As new servers were failing for no explainable reason, IBM enlisted Purafil to determine the source of the problem and protect one of their most valuable assets.

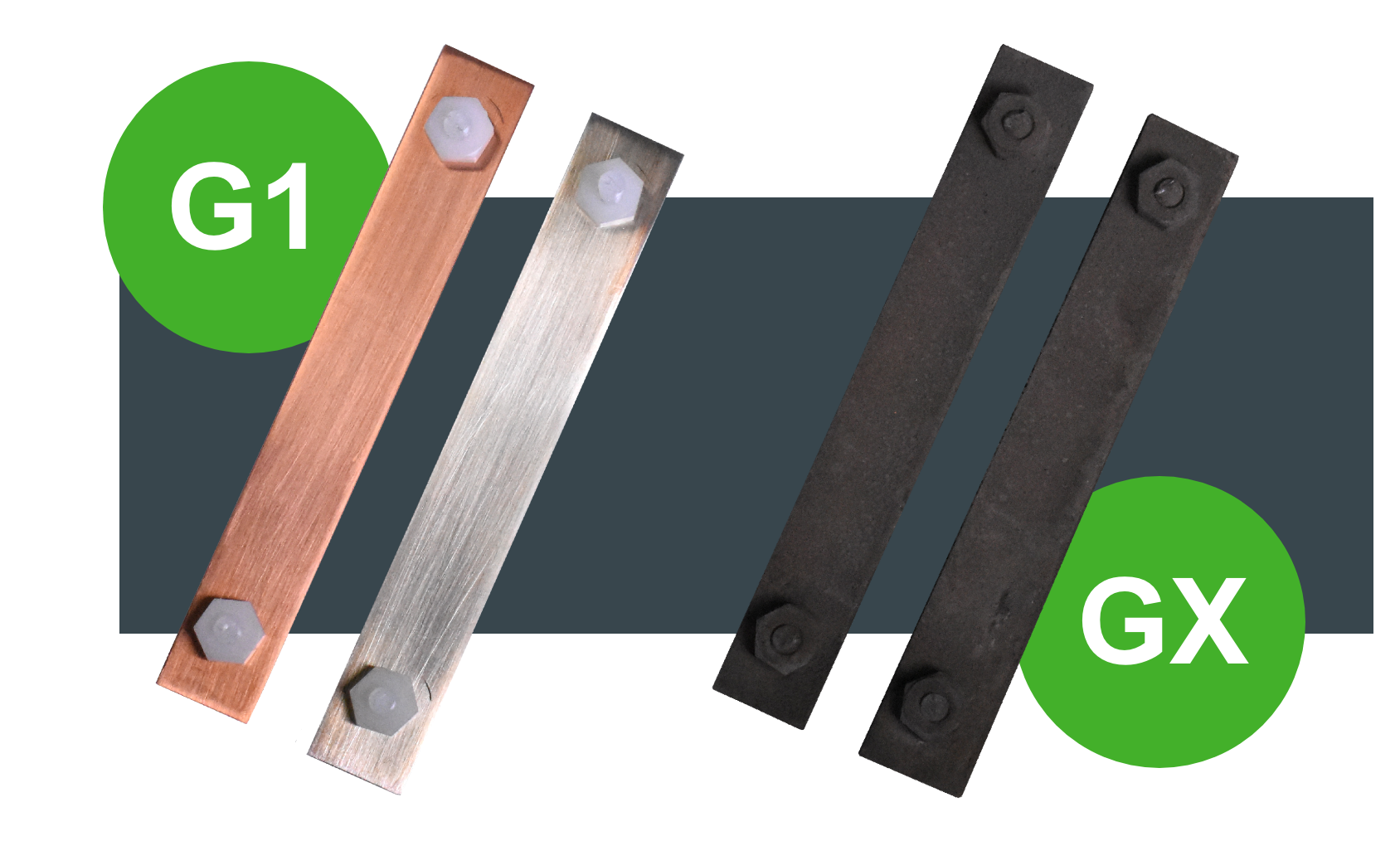

To address the issue at hand, Purafil installed Corrosion Classification Coupons (CCC), which allowed for a more complete picture of what was going on. We also learned that the local environment had high levels of air pollution and airborne corrosive contaminants, which can wreak havoc on critical equipment. The coupons confirmed this by diagnosing a GX air quality level in the manufacturing lab as per ISA71.04-2013.

“Our solution has brought the level down to G1, thus safeguarding the data center. As a result, this location hasn’t experienced any equipment failure due to corrosion or business downtime.”

Data Centers Turn to Purafil for Reactivity Monitoring

INDIA’S LARGEST TELECOM COMPANY

India’s largest telecom company offers wireless broadband, mobile phone, and satellite services throughout Asia. In 2015, they built India’s first Open Network, giving customers access to tower maps, weak spots, strong signal zones, high speed internet and more.

A major OEM customer for electronics notified them of critical electronic card failures due to corrosion and suggested the IT Manager call Purafil for a solution. Since installing the complete Purafil solution, electronics failure has been eliminated, and they continue to maintain an G1 environment. This ensures that corrosion is no longer a factor in this Telecom’s ability to support their customers, and ensure uninterrupted service provided by their critical electronic equipment. That’s the Purafil Peace of Mind.

“Since installing the complete Purafil solution, electronics failure has been eliminated, and they continue to maintain an G1 environment as classified by the International Society of Automation (ISA) Standard 71.04-2013 “Environmental Equipment Conditions for Process Management and Control Systems: Airborne Contaminants”

Ensure Your Facilities Compliance with ISA Air Quality Standards

The International Society of Automation (ISA) has created a standard to measure these environmental conditions. Reactivity monitoring tools like the OnGuard Smart and Corrosion Coupon can help determine which ISA level your buildings air quality falls under.

ISA Corrosion Levels

G1 Mild: Corrosion not a factor on determining equipment reliability

G2 Moderate: Corrosion effects are measurable and corrosion may be a factor

G3 Harsh: High probability that a corrosive attack will occur

GX Severe: Only specially designed and packaged equipment will survive

WE CAN HELP ASSESS YOUR ENVIRONMENTAL RISK FOR CORROSIVE AIR

Free analysis and reporting is Included with all Purafil Corrosive Air Diagnosis Solutions.

WHY PURAFIL?

Corrosion Coupons & OnGuard Monitoring

Purafil’s Corrosion Monitoring Solutions include both silver and copper to test air quality. These metals are representative of the equipment in a data center and can provide insight into how that equipment is being effected by the surrounding environment.

WHY PURAFIL?

Environmental Corrosivity Analysis

In addition to testing, all corrosion monitoring solutions come with a free air quality analysis and results breakdown. With the OnGuard, this analysis happens directly within the unit.

When testing with Corrosion Coupons, after a 30-day testing period, coupons are sent back to our labs — the ONLY corrosive air diagnosis facilities with the ISO 17025:2017 lab accreditation. Our team analyzes the coupons, providing a comprehensive report of the results along with a tailored solution.

WHY PURAFIL?

All at Your Fingertips: From Registration to Reporting

Purafil’s Corrosion Coupon process is uniquely digital. Once registered in the portal, you will be able to track the life cycle of your coupon as it moves through each step, from placement to reporting. Once analysis is complete, you will be notified and directed to your report.

MONITORING TOOLS

FREE ANALYSIS

DIGITAL ACCESS

WHY PURAFIL?

Corrosion Coupons & OnGuard Monitoring

Purafil’s Corrosion Monitoring Solutions include both silver and copper to test air quality. These metals are representative of the equipment in a data center and can provide insight into how that equipment is being effected by the surrounding environment.

WHY PURAFIL?

Environmental Corrosivity Analysis

In addition to testing, all corrosion monitoring solutions come with a free air quality analysis and results breakdown. With the OnGuard, this analysis happens directly within the unit.

When testing with Corrosion Coupons, after a 30-day testing period, coupons are sent back to our labs — the ONLY corrosive air diagnosis facilities with the ISO 17025:2017 lab accreditation. Our team analyzes the coupons, providing a comprehensive report of the results along with a tailored solution.

WHY PURAFIL?

All at Your Fingertips: From Registration to Reporting

Purafil’s Corrosion Coupon process is uniquely digital. Once registered in the portal, you will be able to track the life cycle of your coupon as it moves through each step, from placement to reporting. Once analysis is complete, you will be notified and directed to your report.

What’s Included in the Free Report?