Share

If your paperboard mill has ever experienced production downtime due to corrosion, even just once, you know it can cause a major strain on your production line, budget and staff. Unfortunately, due to the necessary processes in paper manufacturing, this can often feel like an unavoidable part of the job. The good news? This doesn't have to be the case.

Corrosion mitigation solutions are available to help you create a strategy that combats the effects of corrosion before it leads to equipment failure and shutdowns. Purafil is trusted by pulp and paper manufacturers for custom solutions and ongoing monitoring within their facilities — striving to continuously improve, modernize and simplify their corrosive air mitigation services.

Experience in the Field

The experts at Purafil have years of experience working with pulp and paper mills, assisting in their corrosive air mitigation strategies.

Paper Mill, Alabama

A paper mill in Alabama decided to install filtration units in their MCC rooms to prevent corrosion, but after the installation they started to see a huge consumption of filtration material without the expected results. They spent more than a year with the competing supplier trying to correct the issue, until they reached out to Purafil for support to solve their problem.

“Since utilizing Purafil, this critical control room has maintained a corrosion free environment for over 10 consecutive years.”

Paperboard Mill, Macon, Ga.

A major paperboard manufacturer headquartered in Georgia, leading in the design and manufacturing of food grade packaging products, was having difficulty identifying and solving an equipment room air quality issue. Using reactivity coupons and criteria developed by the International Society of Automation (ISA), the mill determined that a critical control room, located on the wet end of the paper machines, continued to indicate a harsh and corrosive ISA “GX” environment. If left unresolved, the air quality would eventually shut down production because of equipment failure.

Downtime at this mill can run in excess of $100K per hour, so an effective solution was crucial. After years of attempts and unsuccessful resolutions by their previous supplier, Purafil suggested a solution. By correctly sizing and supervising installation of a Purafil Tub Scrubber, using Purafil’s high removal capacity Puracarb media, and assisting in resolving construction issues (i.e. proper room sealing, HVAC placement, and ducting), a clean and sustainable ISA “G1” rating was achieved — and maintained.

By providing a solution to their most difficult filtration problem after others had failed, Purafil became the provider of choice, and the clean air partner for the remaining control rooms and motor control centers throughout the facility.

The Purafil Partnership

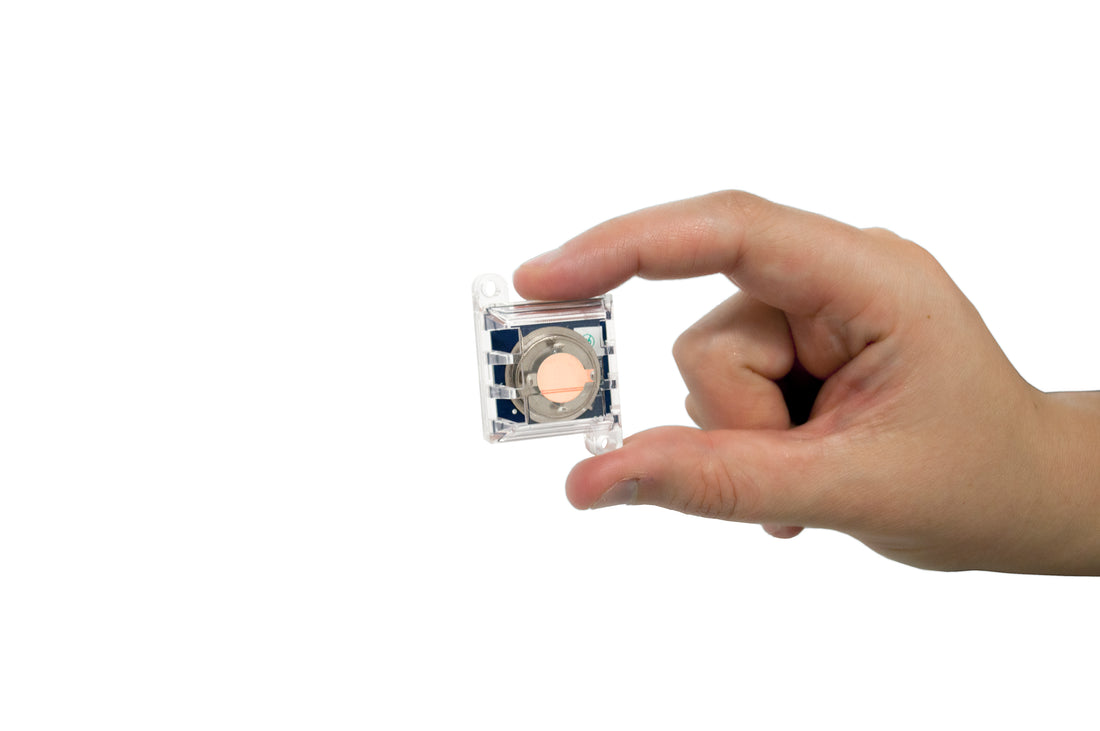

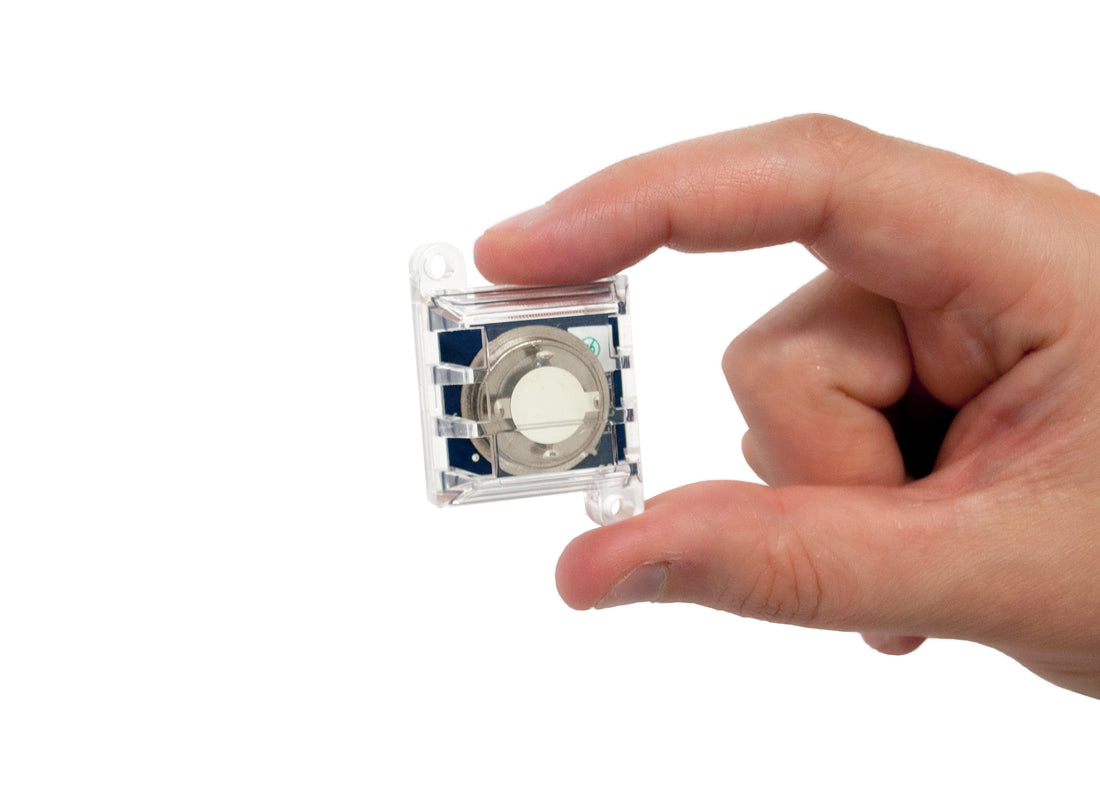

From the very beginning, our goal has been to make the world safer, healthier and more productive. Our trusted team of experts will come alongside your team to create a corrosive air strategy that works best for your mill or help streamline an existing process where needed. Purafil’s corrosion mitigation services address all necessary steps, from diagnosis to solutions with our full suite of corrosion mitigation tools — including Corrosion Coupons, air scrubbers, filtration media and OnGuard monitors.

Experience the Purafil peace of mind — Let us take this problem off your plate so you can focus on what matters most in your mill. Shop our reactivity monitoring solutions or contact an expert to discuss your corrosive air strategy today!

0 comment