Share

For anyone new to the concept of corrosion monitoring, there are so many factors it can become confusing quickly. What is the difference between passive and active corrosion diagnosis? Which is a better fit for my facilities? In this guide, we’ll outline the main points you need to know about corrosive air monitoring.

Why Do I Need to Monitor Airborne Contamination?

Monitoring the quality of air in a facility is important for a spectrum of industries. Whether you work with industrial equipment, sensitive Data Centers or priceless works of art, having a process in place for the monitoring and mitigation of airborne contaminants can be imperative to the longevity of your business. When left unchecked, environmental factors can wreak havoc on mission-critical electrical equipment or cherished pieces of history. Having a corrosive air monitoring procedure in place can ensure reliability & extend the life of the equipment in your facilities.

What are my Options When it Comes to Monitoring Methods?

Purafil offers two main types of corrosive air monitoring tools. These tools are as follows:

- Passive monitoring

- Active monitoring

Passive Corrosion Diagnosis

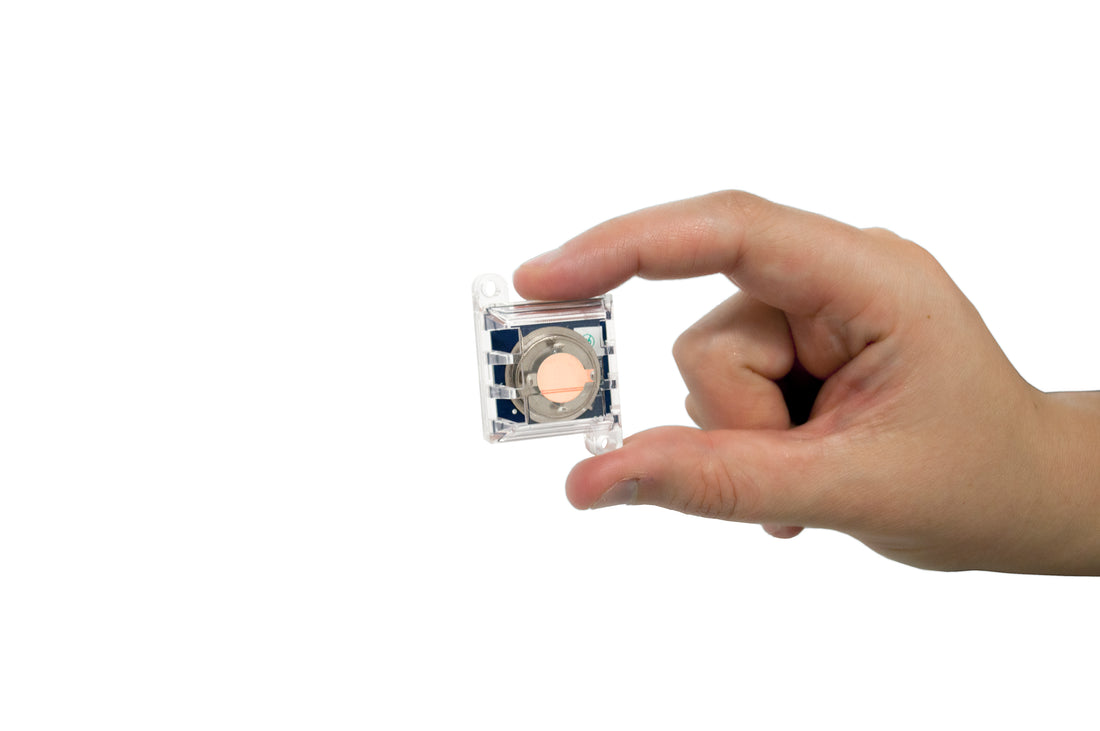

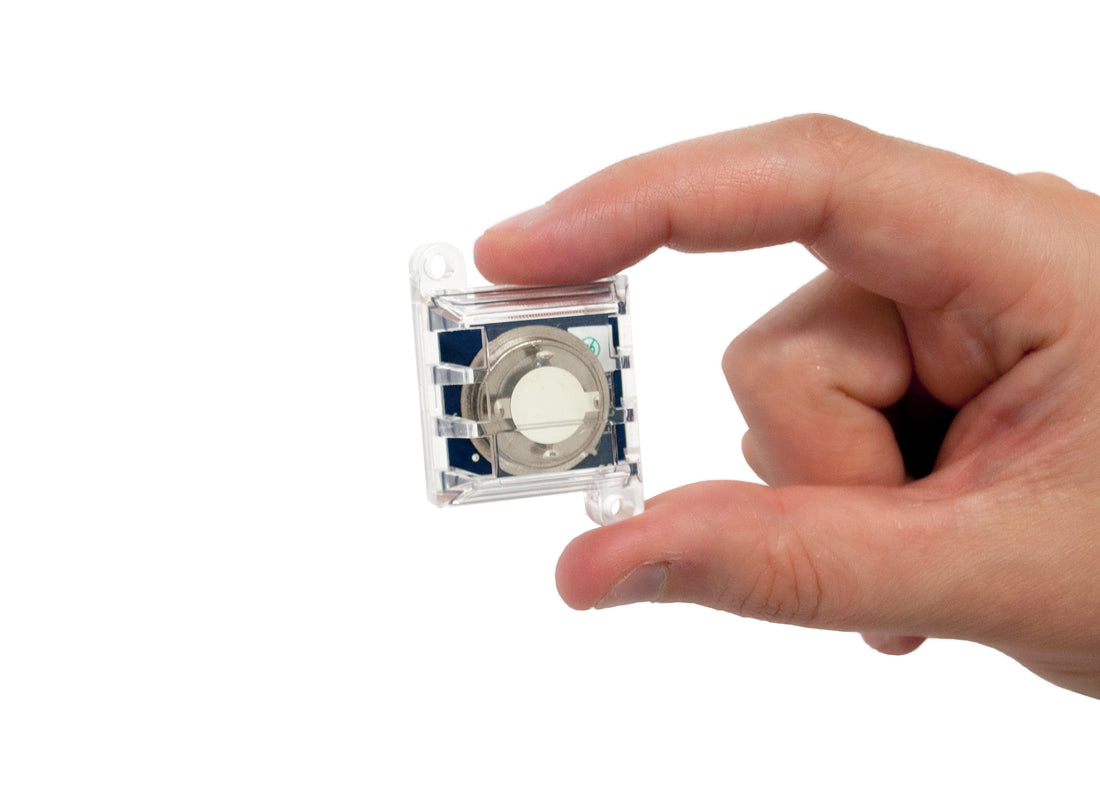

Passive corrosion diagnosis occurs over a 30-day period and requires the placement of a Corrosion Coupon. Corrosion Coupons are one-time use and must be returned to our lab for testing and analysis after the 30 day exposure period.

Corrosion Coupon Models

There are two different models of the Corrosion Coupon — Corrosion Coupon and Corrosion Coupon+. Both use copper and silver strip to mimic the sensitive connections and components in your electronic equipment. The difference between the two is that the Corrosion Coupon+ contains a temperature and relative humidity logger.

Lifecycle of a Coupon

The lifecycle of a coupon can be broken down into 5 easy steps:

- Coupon Registration: Before placing the coupon in the test area, the coupon is registered in the online portal. This allows the user to track the coupons journey digitally and access their final results.

- Place the Coupon: Once registered, the coupon can be placed in the intended testing site. We recommend 1 coupon per air vent in critical spaces.

- Installation Period: Once placed, the coupon must remain in its testing site for the 30-day installation exposure period. This is critical to getting accurate results, as the coupons' corrosivity will be measured against a 30-day reactivity rate.

- Laboratory Analysis: After installation, the coupon gets shipped back to our ISO 17025:2017 accredited laboratory — the only corrosion diagnosis lab with this prestigious certification.

-

Results & Solution: After analysis, users will be notified that their results are now available in the portal. The report includes as follows:

- Summary of Results

- Corrosion Film Composition Projections up to 5 years

- Equipment Reliability Correlation Data

- ISA Severity Level Classification

Active Corrosion Diagnosis

Active corrosion diagnosis provides results in real-time through the use of Purafil’s OnGuard monitoring system. OnGuard is easy to install and has a long service life — sensors do not need replacement until 4000 Angstroms of cumulative corrosion growth. Results are accessible through an internal data logger that stores the results. They can also be accessed through the internet or directly transmitted to a process control system.

OnGuard Models

There are two different models of the OnGuard — OnGuard 4000 and OnGuard Smart. The difference between the two is that the OnGuard Smart has the added ability to measure room air pressure. This is recommended if you already have a corrosion solution in place for easy ongoing monitoring.

Benefits of Active Monitoring

- Diagnosis in real time — no 30 day wait or return shipping required.

- Ability to determine precisely when changes occur in your facilities & help diagnose the source of corrosion

- Provides incremental and cumulative corrosion data

- Direct interface provided by the backlit LCD and keypad

- Accurate within ± 0.5-1% of full span

What Comes Next After Monitoring?

Purafil is dedicated to making the world safer, healthier, and more productive. After results become available, we can help determine a personalized solution, whether that is continued monitoring or a comprehensive corrosion mitigation plan. In addition to monitoring tools, Purafil offers a full range of air scrubbing systems that can be used to combat a corrosive environment.

Interested in taking the first step towards contaminant-free air? You can trust our team of experts to create a personalized strategy tailored to what your facility needs. Shop Corrosive Monitoring Solutions to get started.

0 comment