Share

Free cooling is seen as an economical way to cool equipment but it could be leading to costly equipment damage down the road. Free-cooling allows external airborne contaminants into data centers, which could cause corrosion on mission-critical electrical equipment. This could ultimately lead to downtime and repairs, costing data centers thousands of dollars per minute.

What is Free Cooling?

Years ago, energy was cheap and data centers were sealed to the outside world to protect them from unauthorized entry, as well as outside pollution. They generate heat 24/7 and required continuous air condition to keep internal temperatures in check. This wasn’t too cost prohibitive, but as energy and operating cost continued to rise, so did the desire to reduce dependency on air conditioning. Free cooling is the utilization of outside air to cool data center equipment and avoid overheating. The ability to provide “free” cooling for data centers by bringing in cooler outside air has been seen as a relatively economical way to cool infrastructure equipment. You can utilize the pre-existing air and environment to do something other facilities are paying for with expensive cooling systems. Sounds great, right? Not exactly.

Ambient Air and Airborne Contamination

Although free-cooling allows for large cost savings up front, it could be costing data center owners more in the long run by allowing airborne contaminants direct access to vulnerable electrical equipment. This could lead to devastating consequences when it comes to the longevity of electrical equipment.

Utilizing outside air for cooling invites uncontrolled conditions into your facilities. Environmental factors such as harsh and corrosive pollutants and humidity can then wreak havoc on the inner workings of electrical equipment. This problem is only exacerbated by RoHS lead-free regulations in electrical equipment, making equipment more susceptible to corrosion than ever before.

Any unplanned downtime associated with equipment failures could be detrimental to a data center’s bottom line and productivity. On average, it costs data centers $300K an hour or $5,600 /minute when shutdown occurs.

Understanding Your Environment

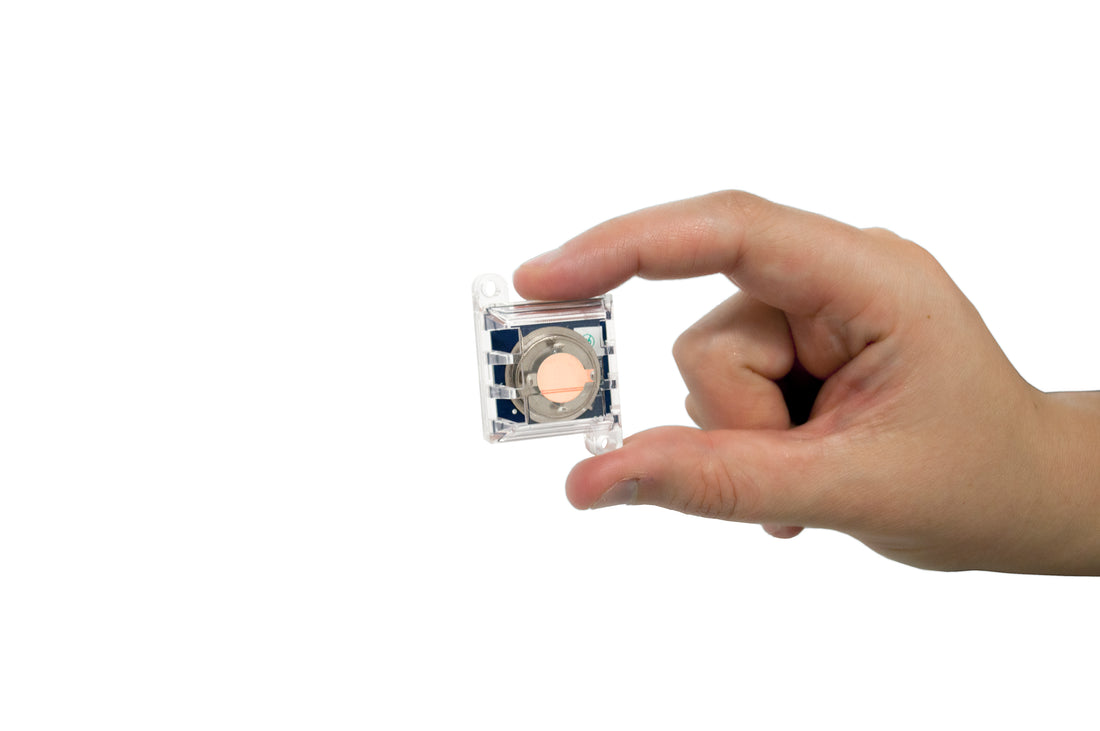

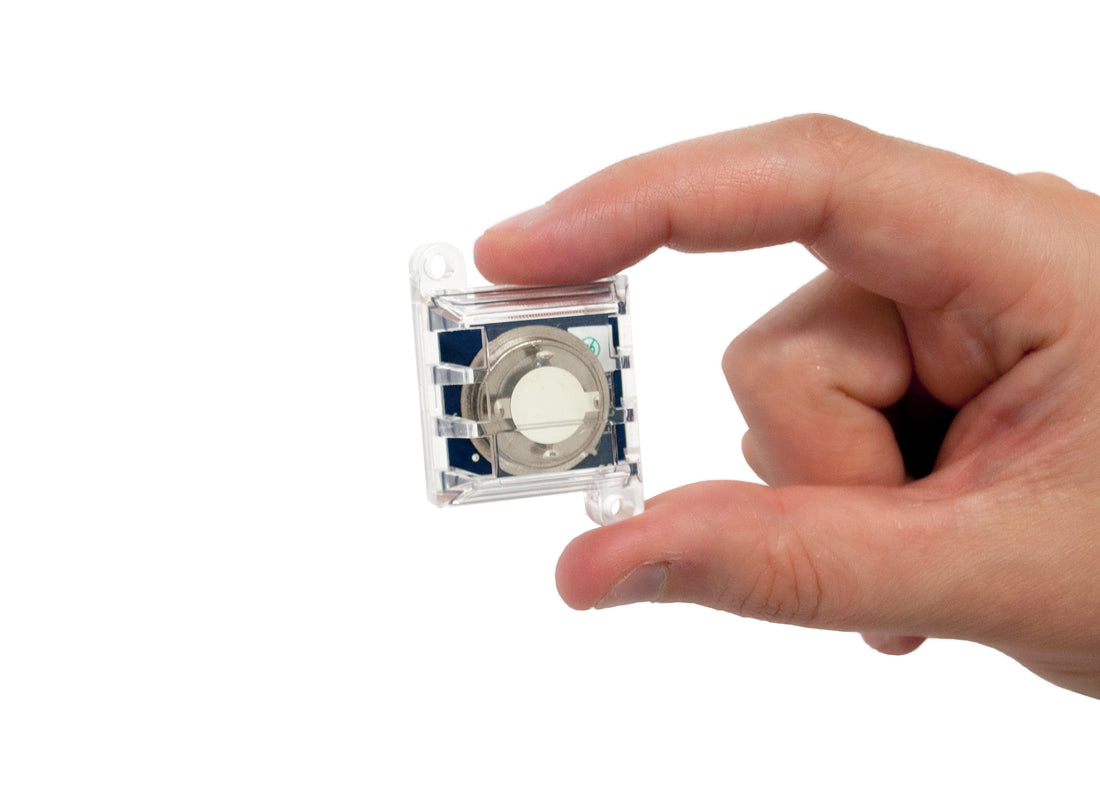

The first step to avoiding these costly breakdowns is having a clear picture of a facilities environment. Frequent monitoring ensures you always have an idea of how corrosive your air is. Once a corrosive environment is identified, solutions can be put in place to mitigate the threat.

Purafil offers a full spectrum of corrosion monitoring solutions, with passive diagnosis offered with corrosion coupons and a more active strategy with the OnGuard system. Contact us, Purafil’s team of air quality experts can help you devise a plan for your facilities.

0 comment