Since installing the complete Purafil solution, electronics failure has been eliminated, and they continue to maintain an G1 environment as classified by the International Society of Automation (ISA) Standard 71.04-2013 “Environmental Equipment Conditions for Process Management and Control Systems: Airborne Contaminants” - India’s Largest Telecom Company

Since utilizing Purafil, this critical control room has maintained a corrosion free environment for over 10 consecutive years. - A Major Paperboard Manufacturer

Purafil was selected because of their experience in the industrial marketplace and superior performance of their air purification systems. Purafil provided the technical knowledge and equipment necessary to build controlled environments that would protect production processes, and meet the standards established by the International Society of Automation (ISA). - World’s Largest Refinery

"Together, we developed an environmental control system that now works behind the scenes, protecting Michelangelo’s delicate work for future generations." - Representative, Preserving the Masterpiece in the Sistine Chapel

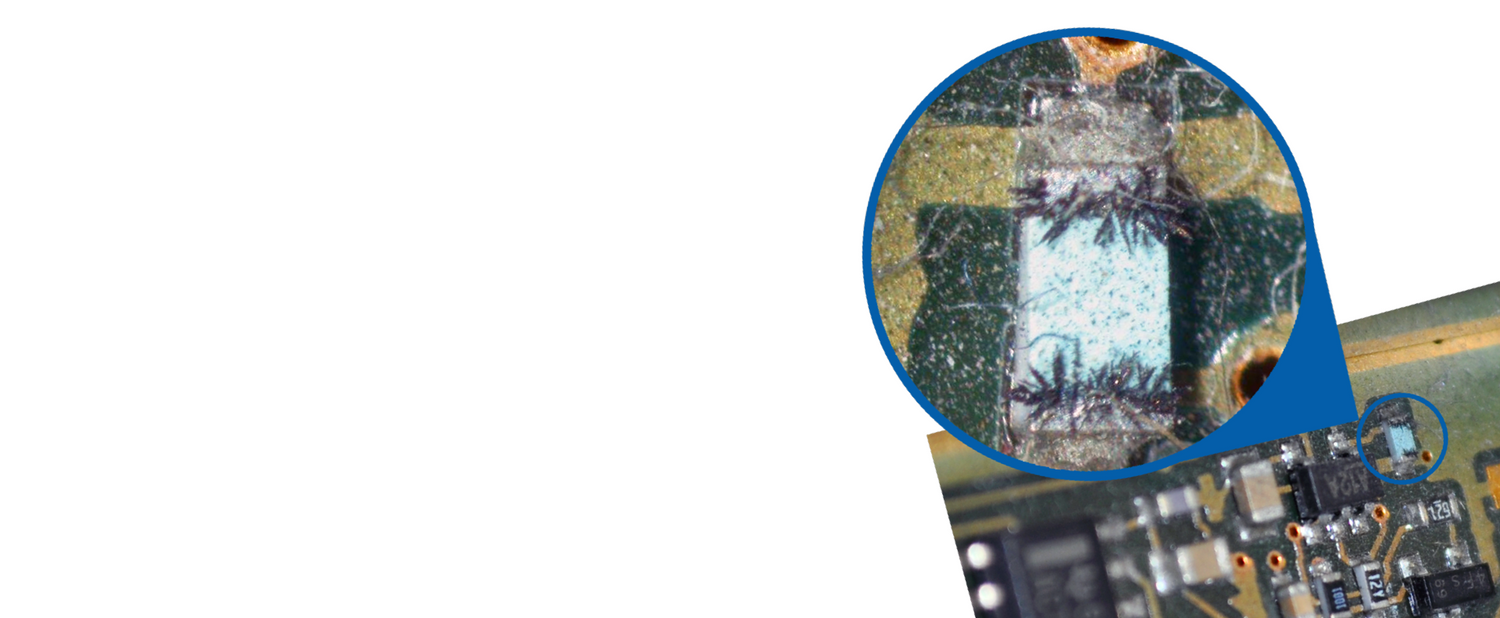

THERE IS NO EXCUSE TO HAVE CORROSION BASED ELECTRICAL FAILURE

Increase reliability & extend the life of the equipment in your facilities

CORROSION CONTROL

SUCCESS STORIES

CORROSIVE ENVIRONMENTS

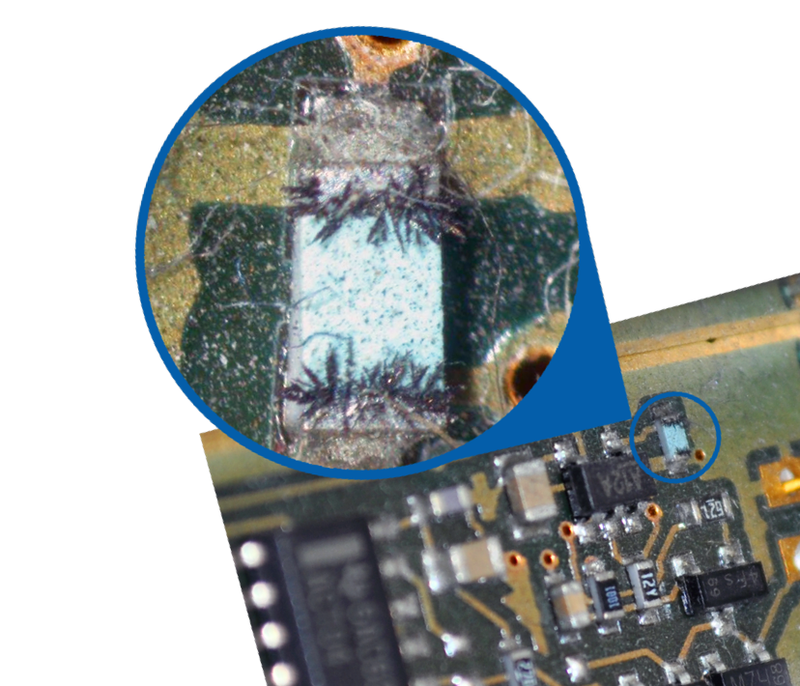

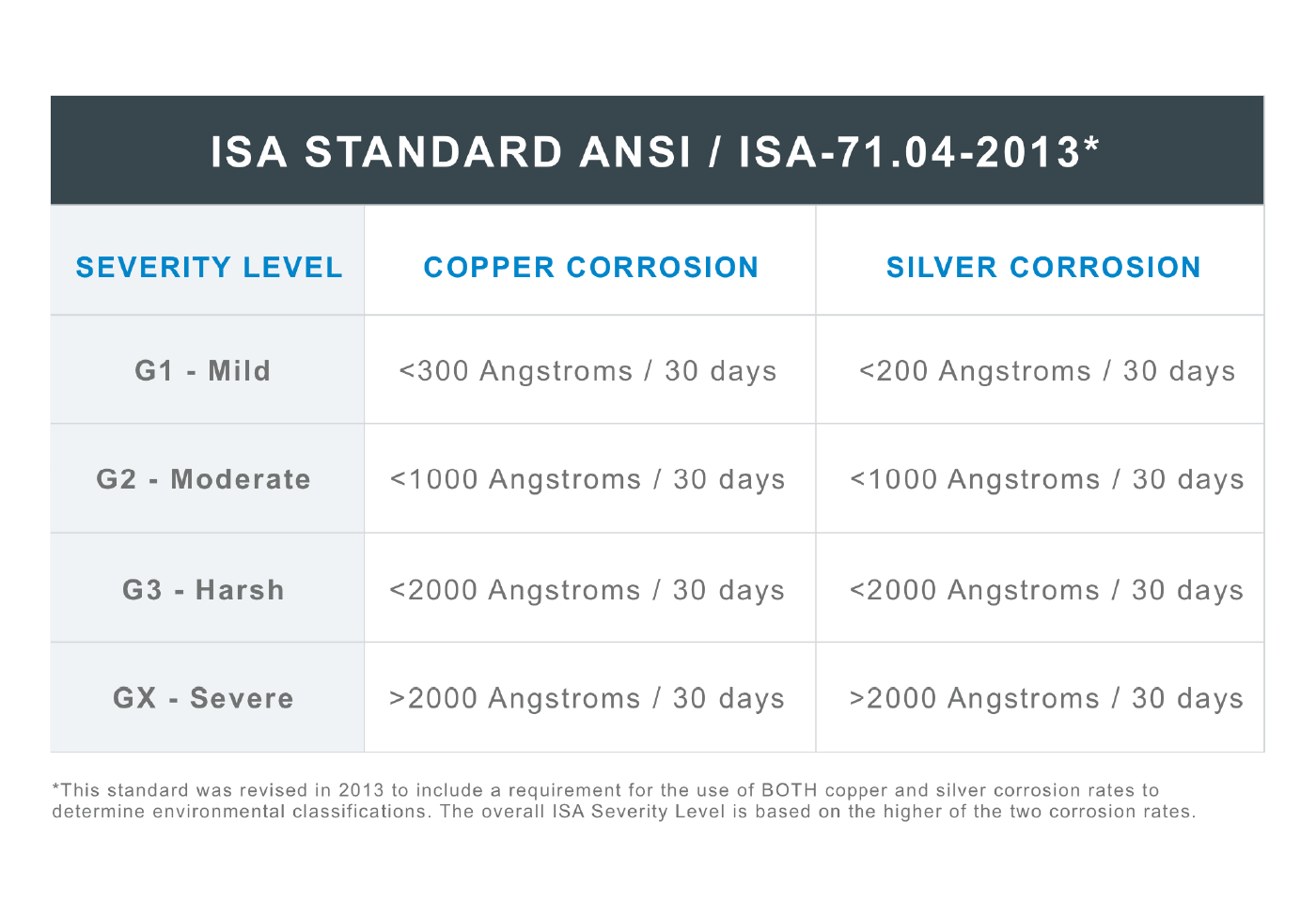

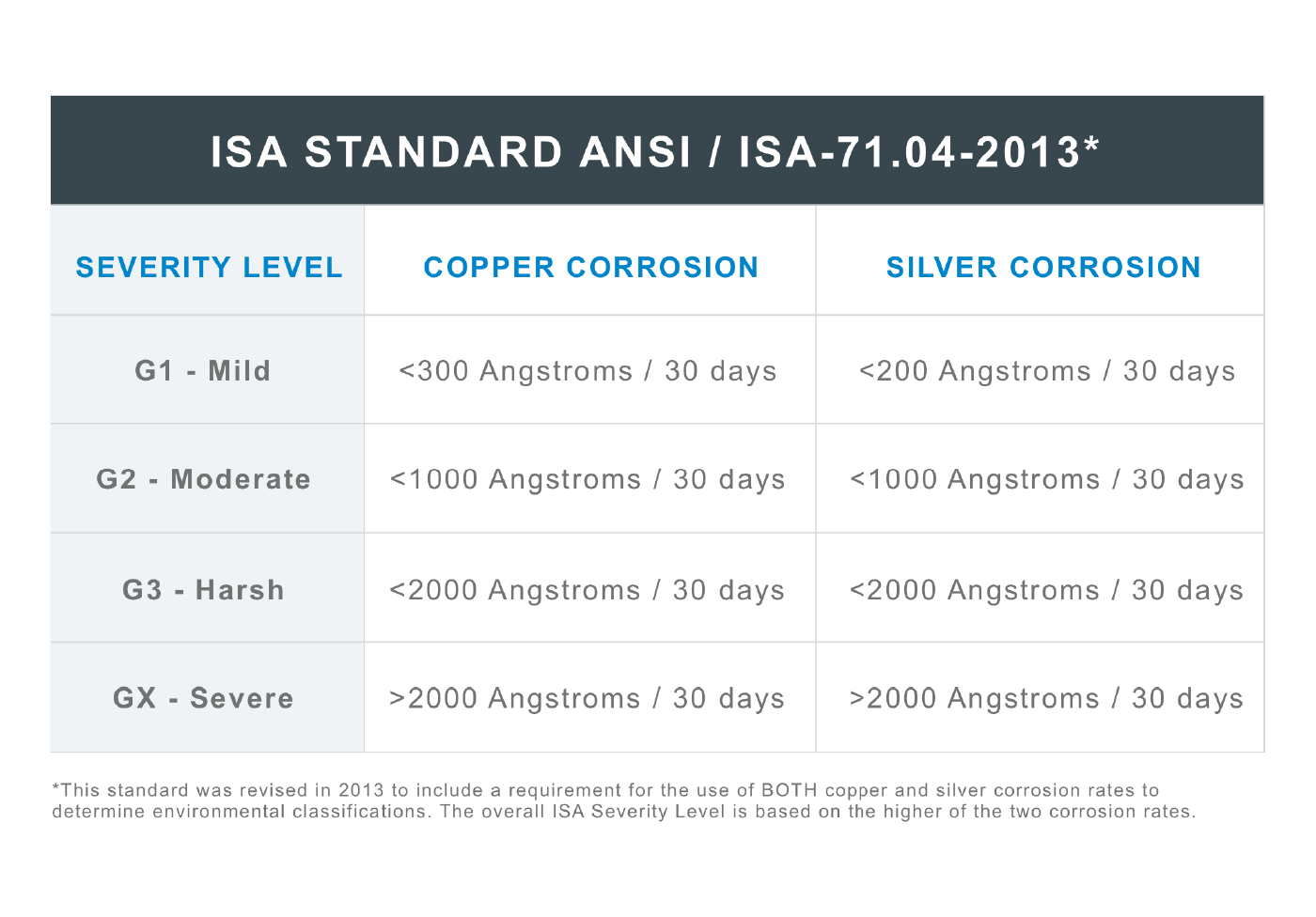

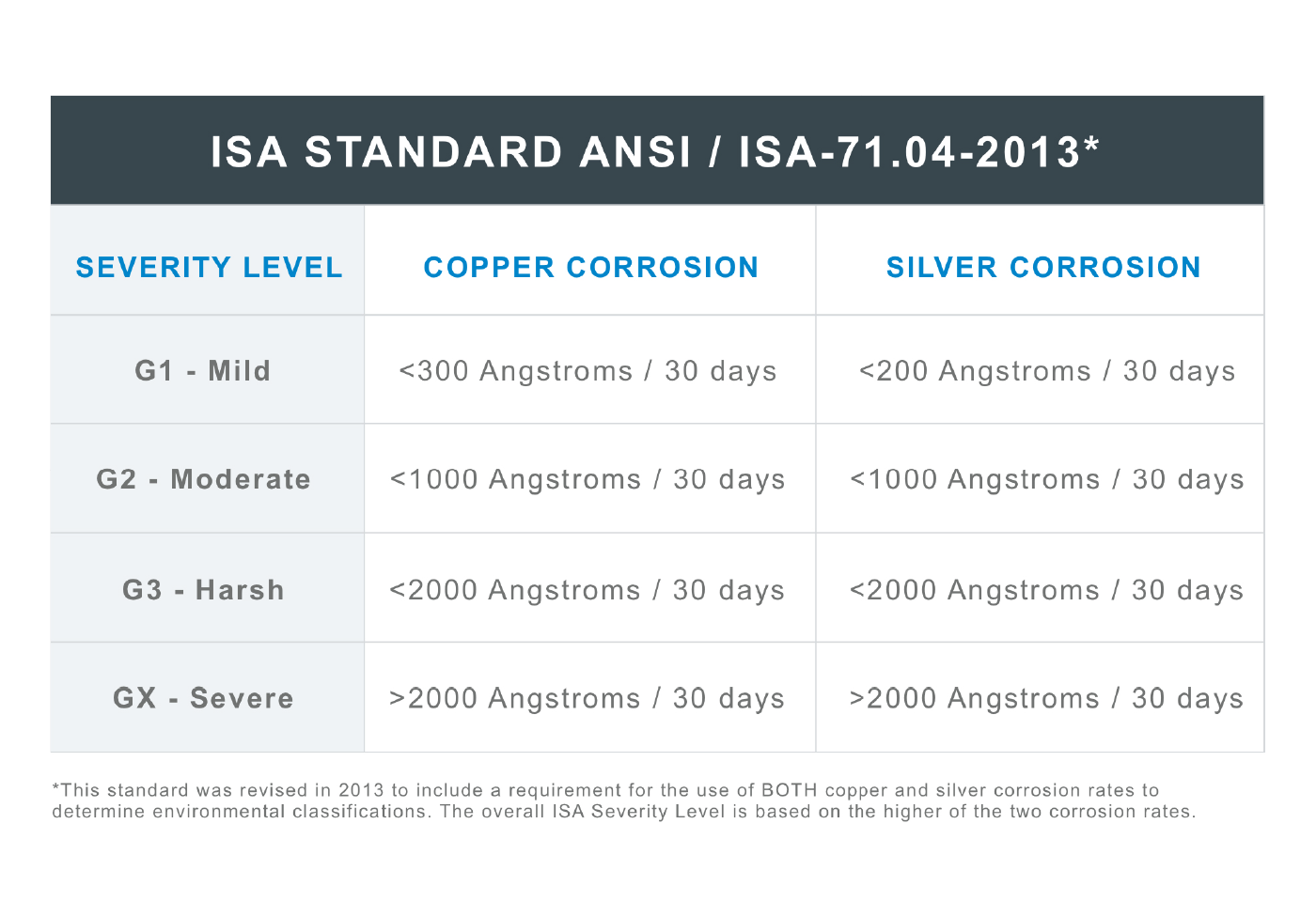

4 CLASSES OF AIR QUALITY

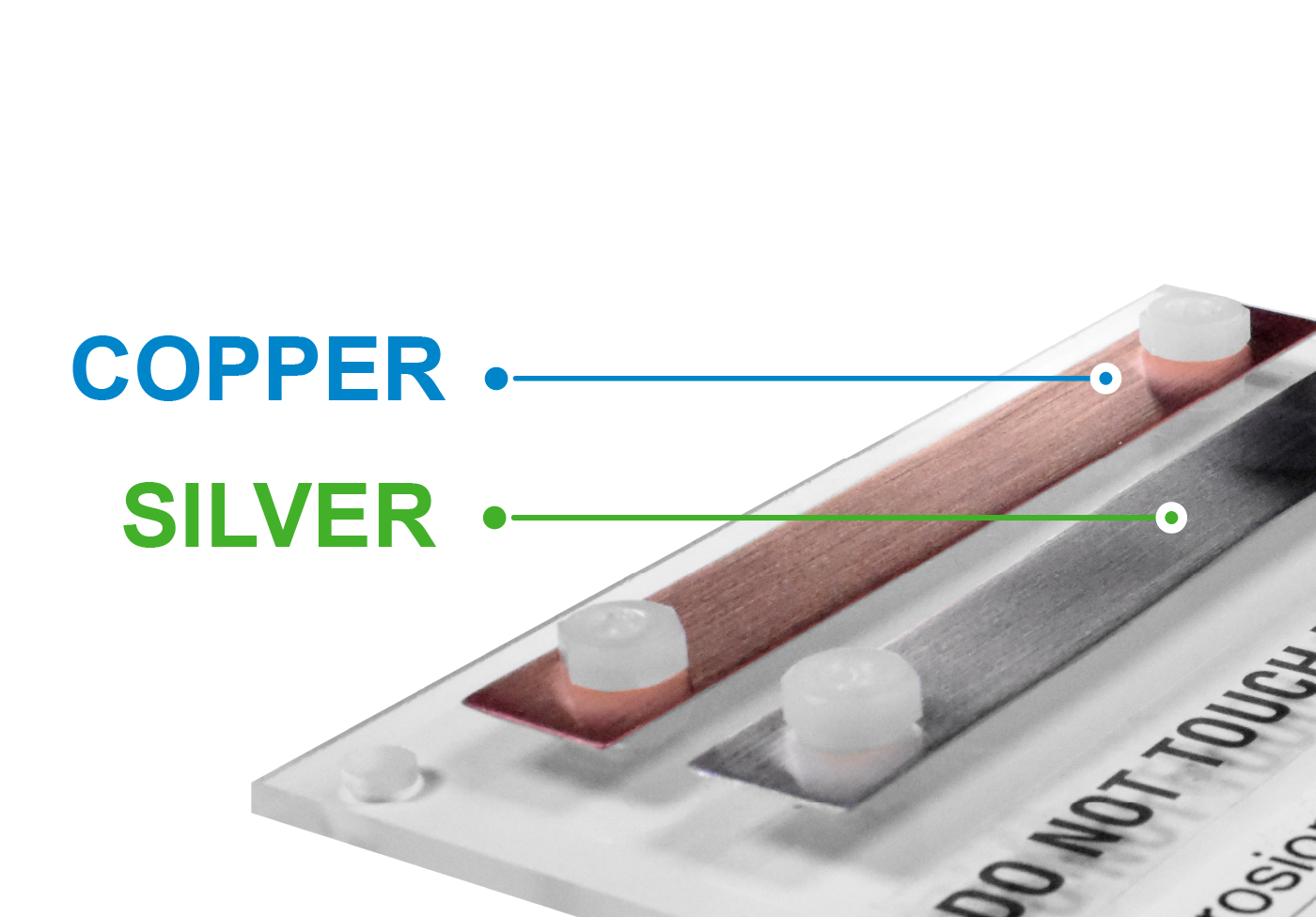

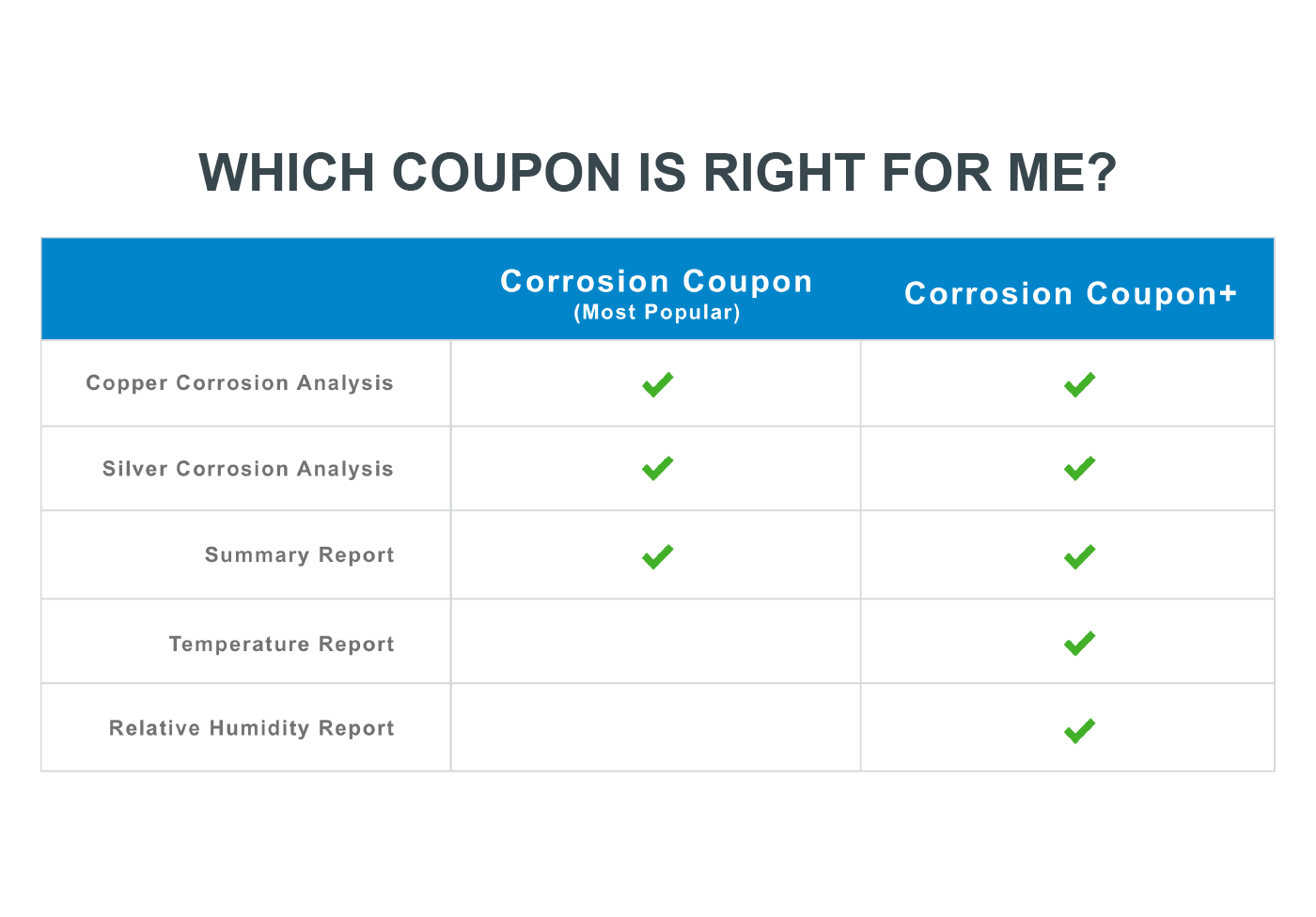

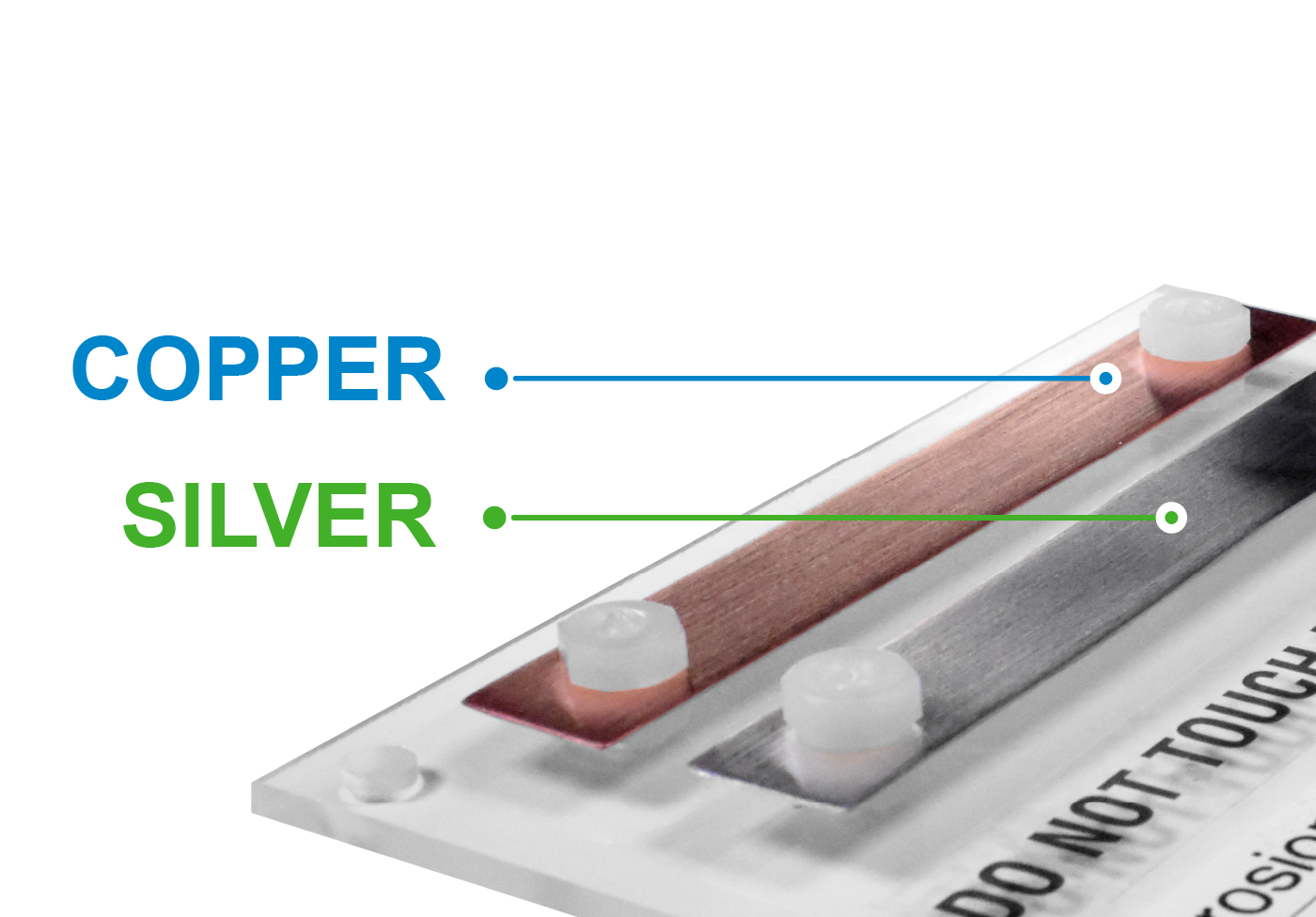

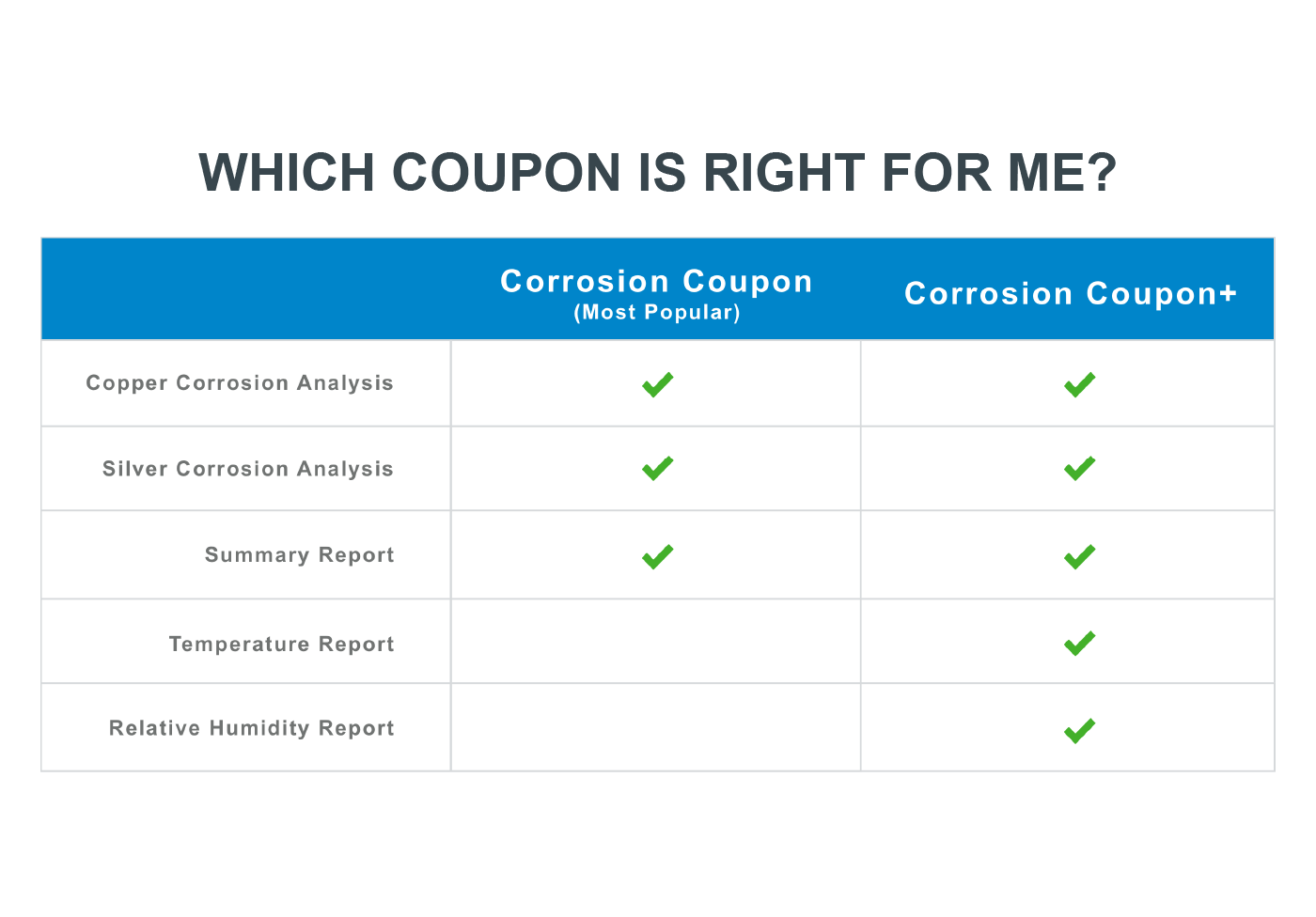

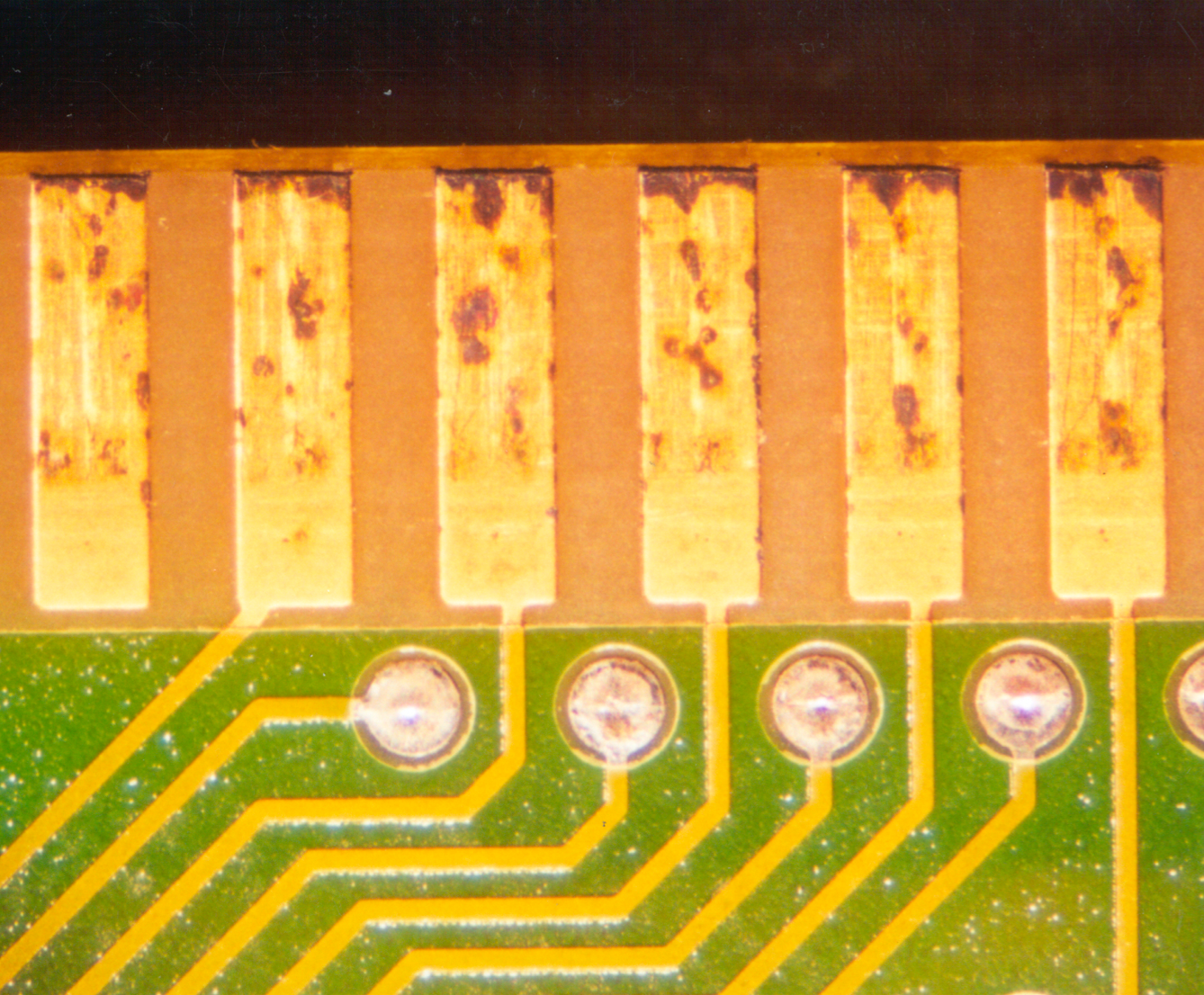

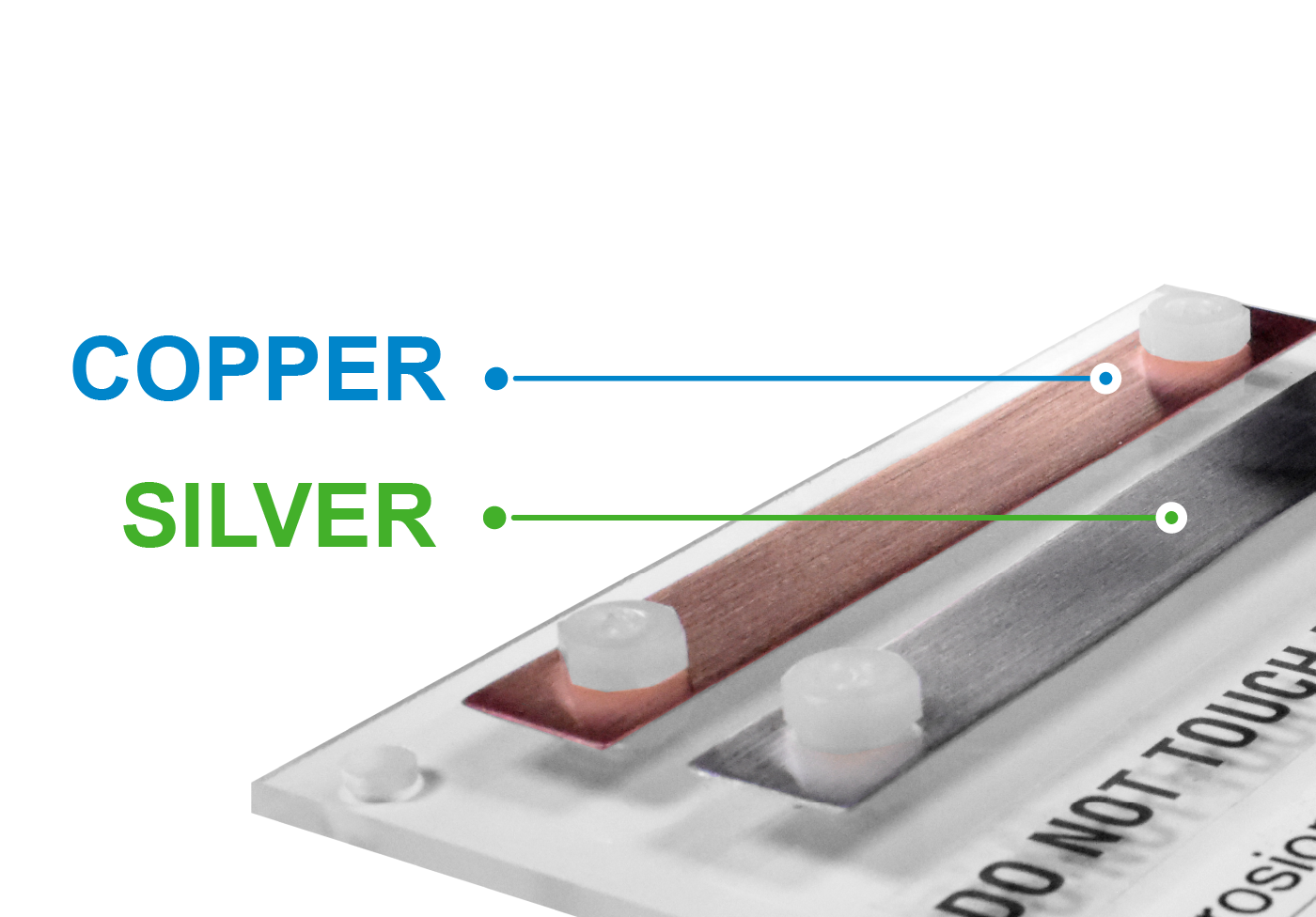

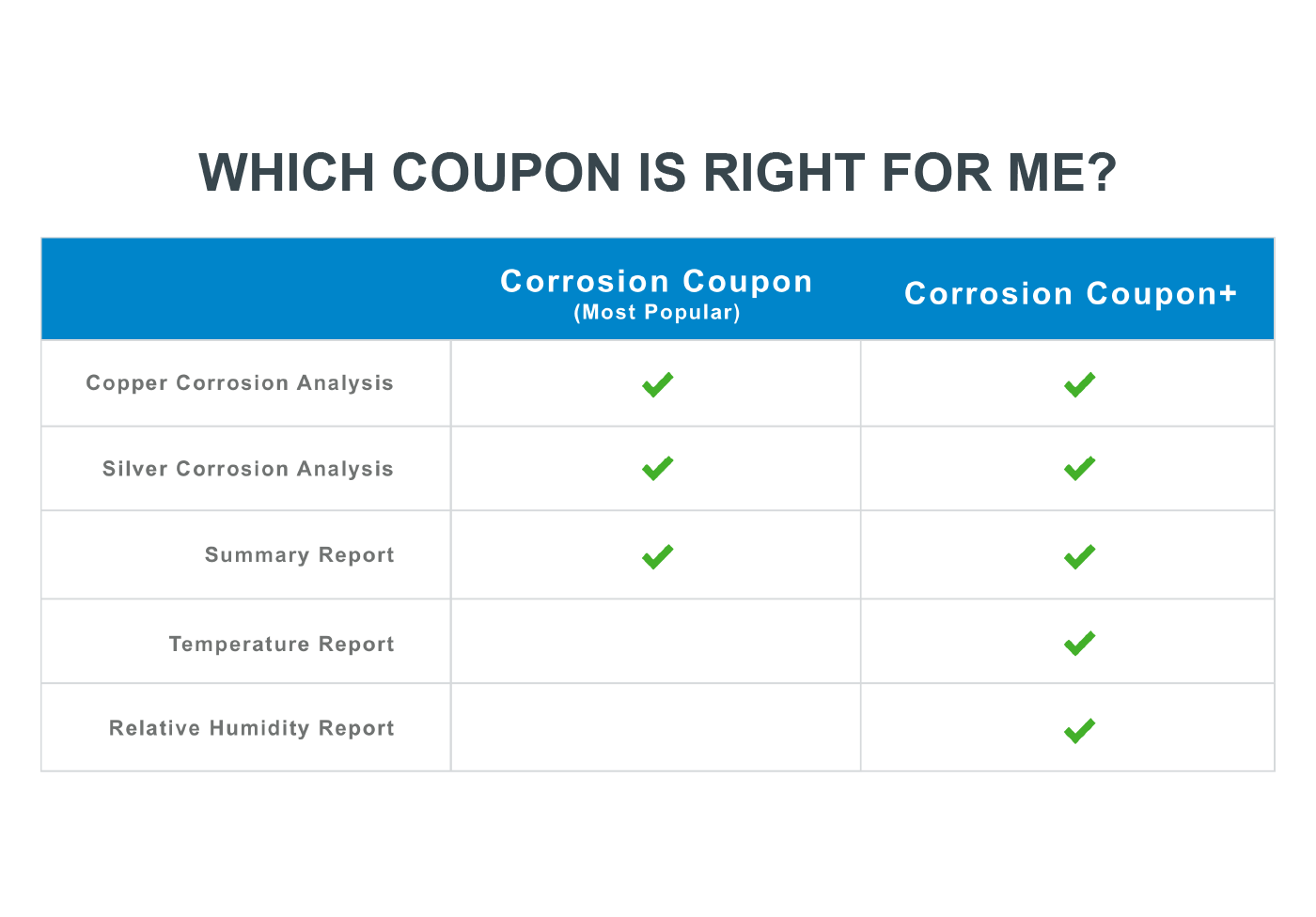

Corrosion Coupons have a silver & copper strip that is representative of the equipment in your facilities. Below are the 4 classes of air quality & their effects on metal.

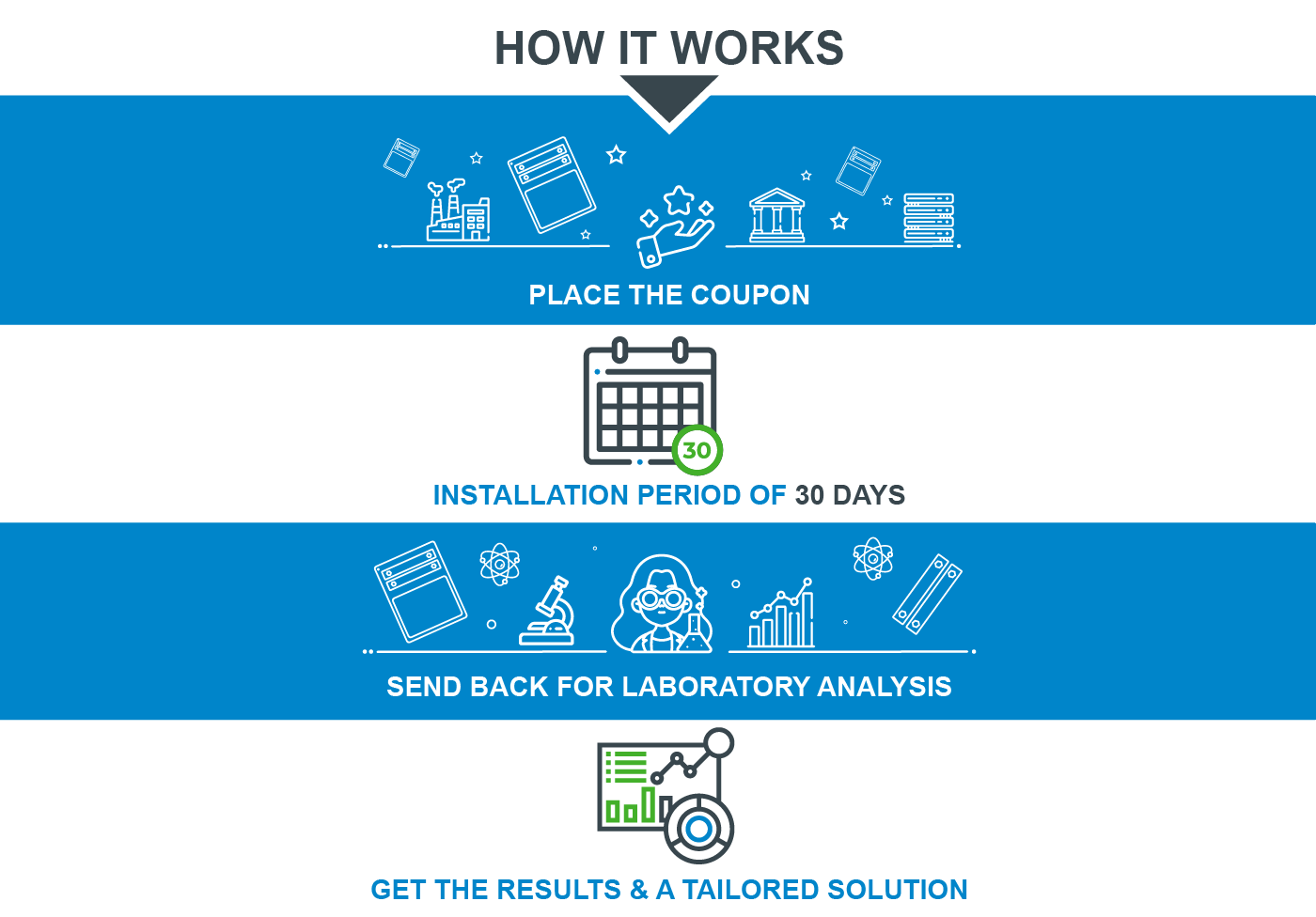

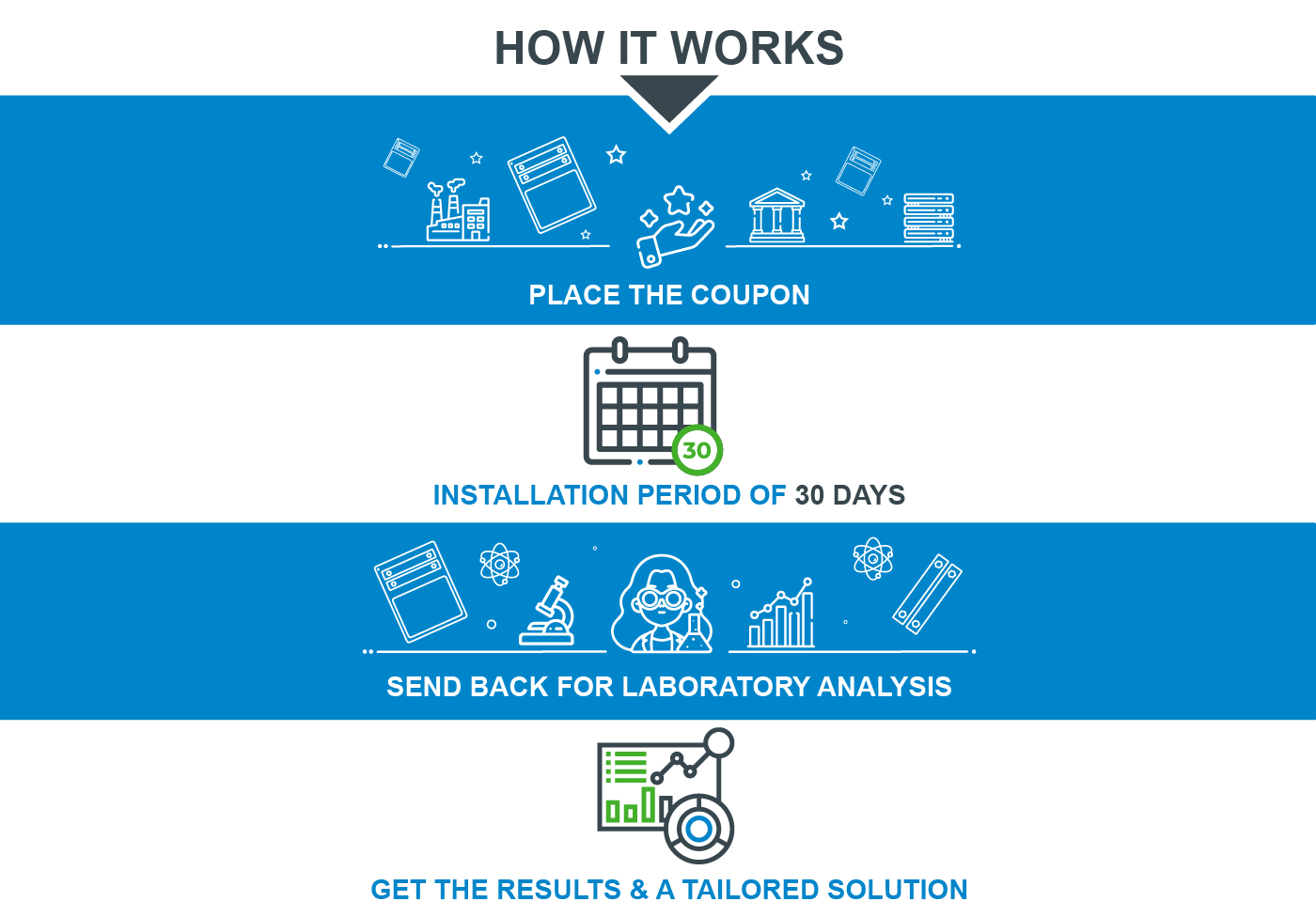

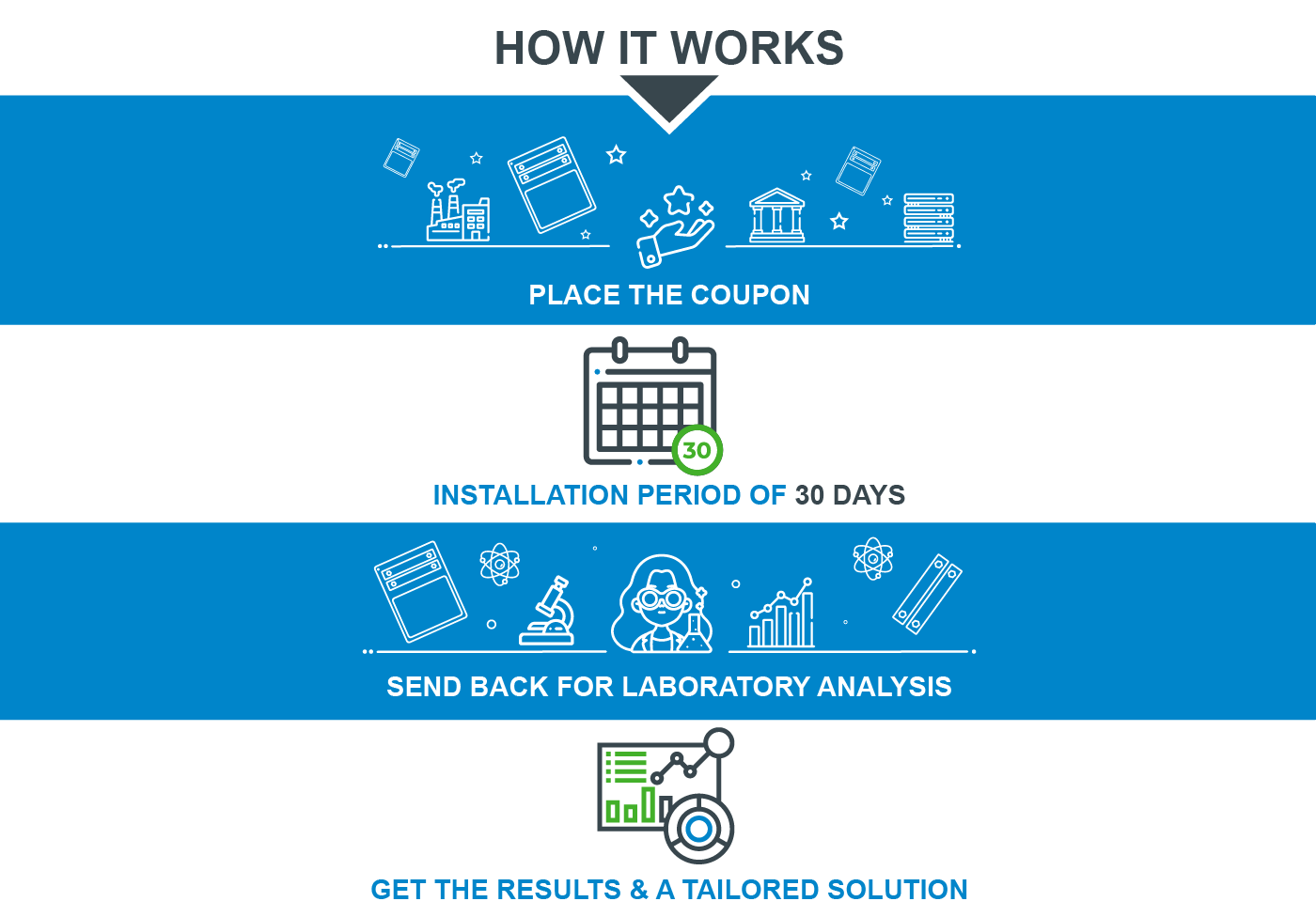

DIAGNOSIS OVER A 30-DAY TIME PERIOD

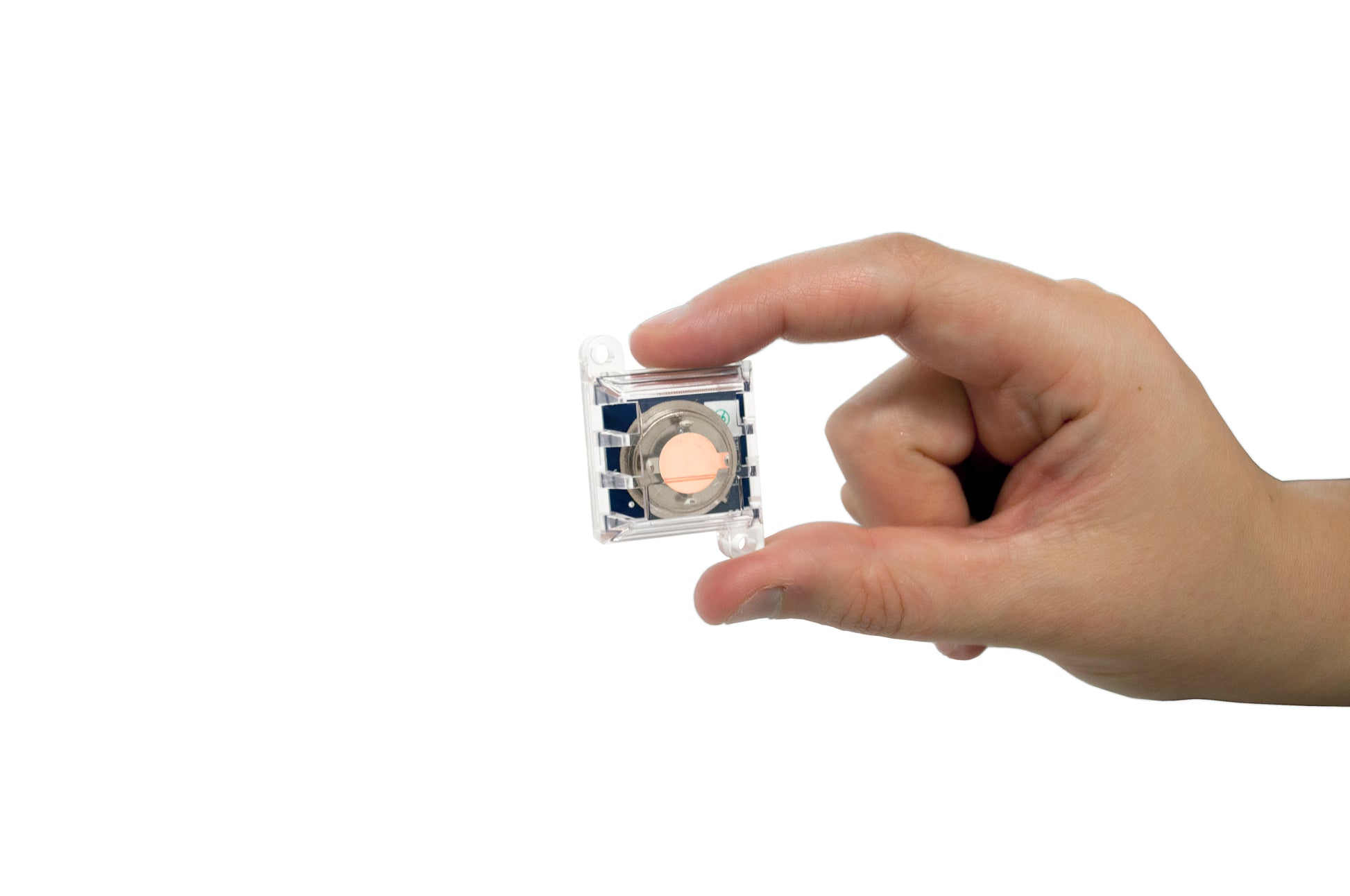

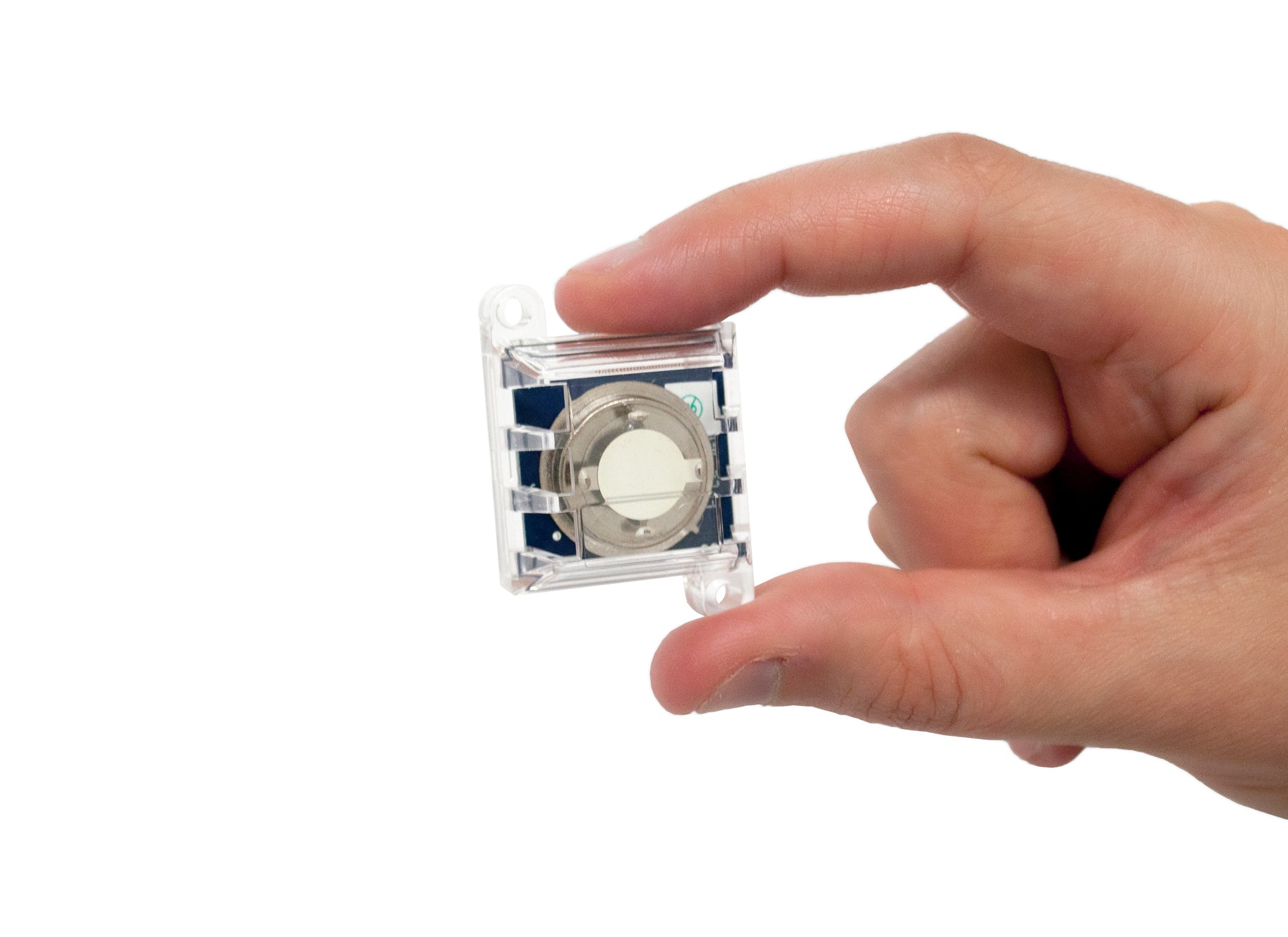

PASSIVE CORROSION DIAGNOSIS

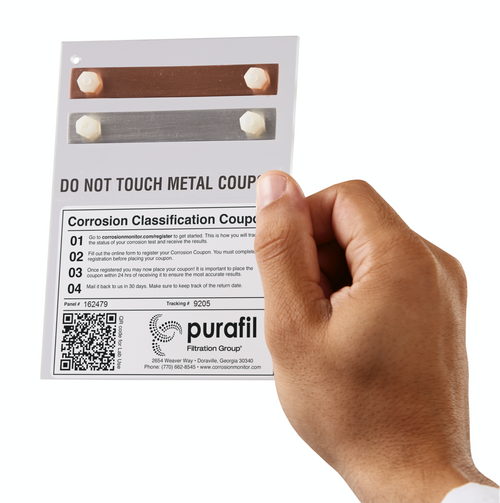

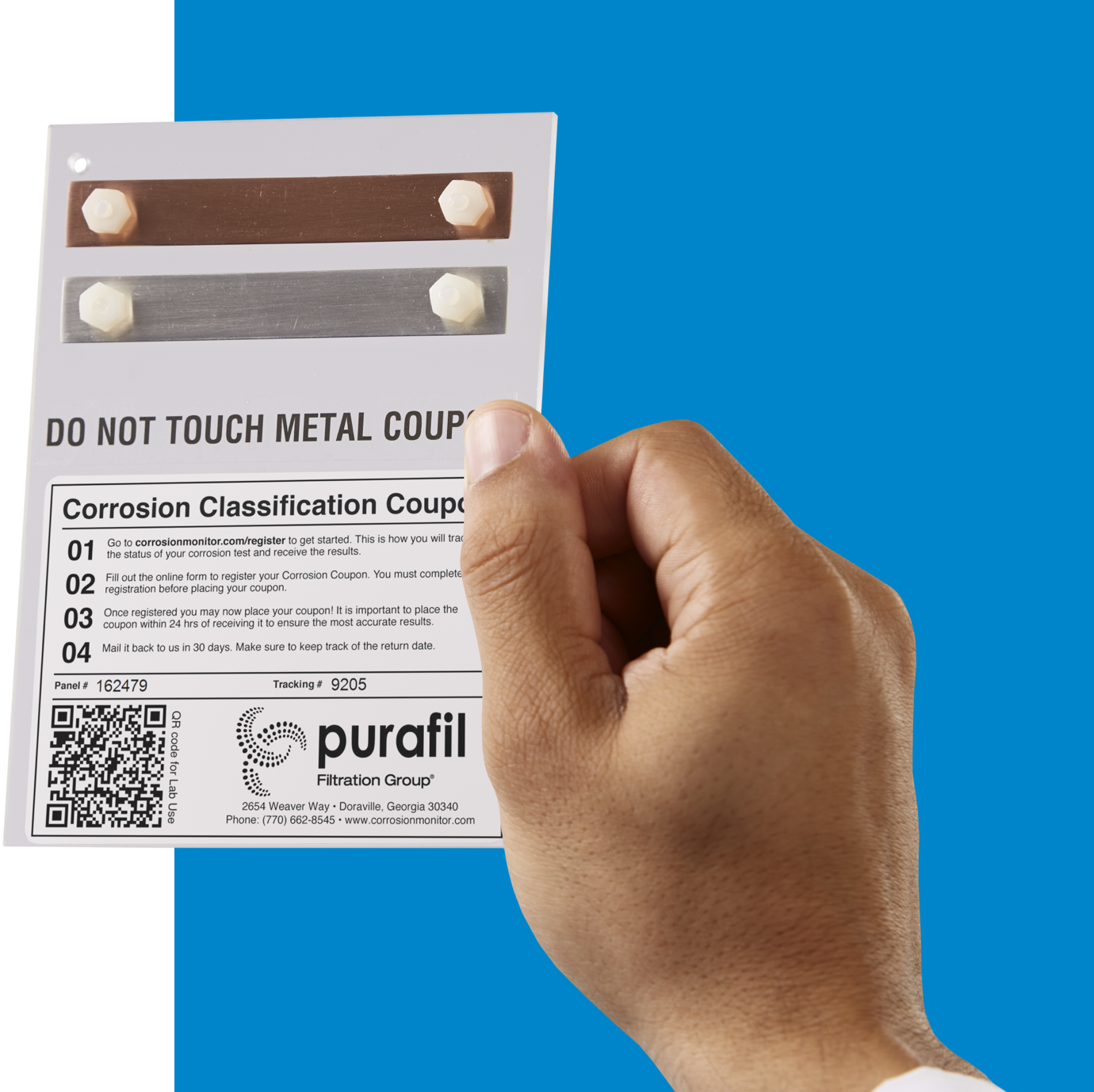

Corrosion Coupons have a silver & copper strip that is representative of the equipment in your facilities. When placed in an environment, the one-time use coupon provides a sample to diagnose if there was any detectable corrosion that occurred over a 30-day time period.

Scientifically Supported, Reliable Results

Easy Installation & Data Gathering

Vital for Determining Corrective Solutions

Corrosion Coupon

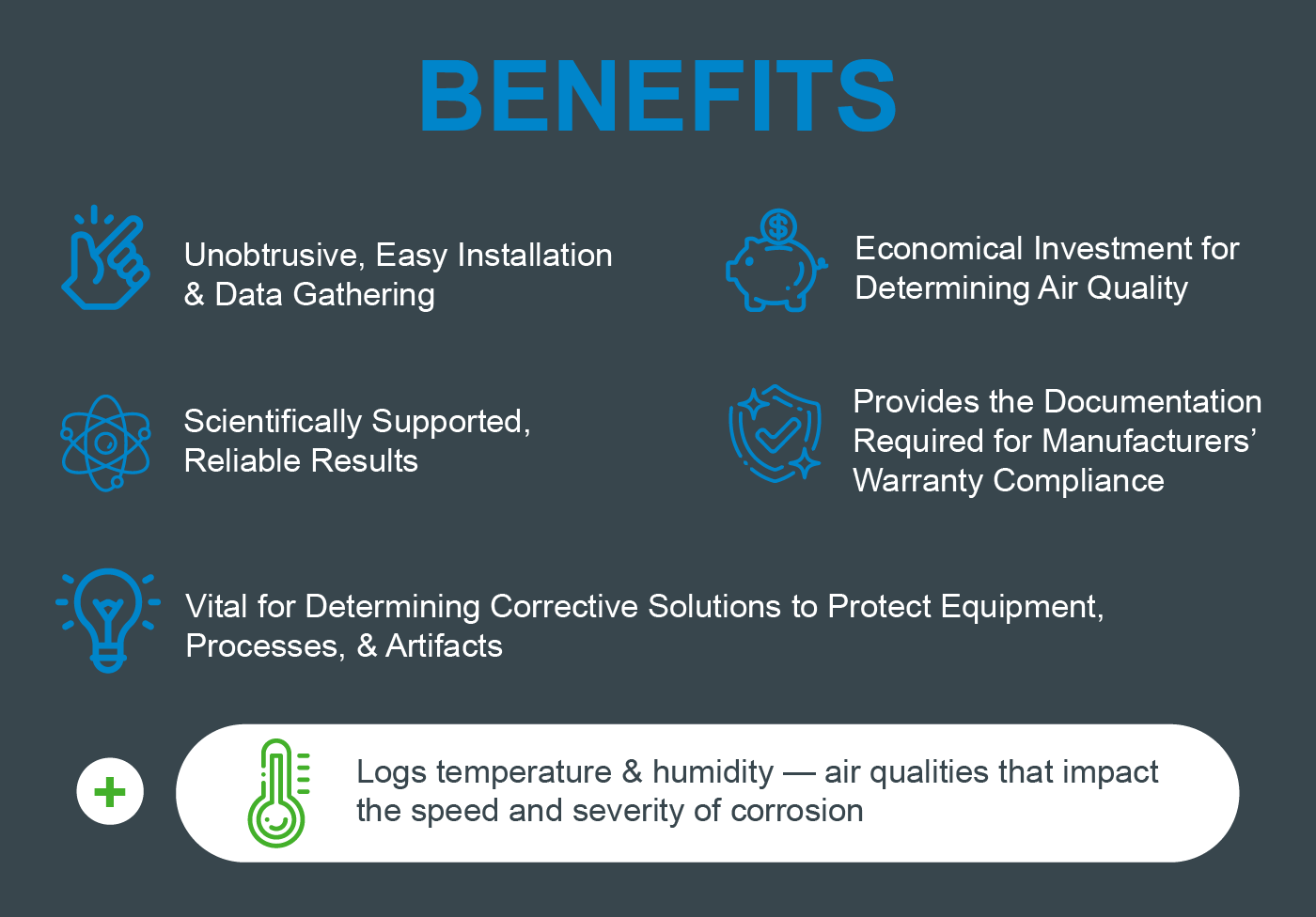

- Unobtrusive, easy installation and data gathering

- Economical investment for determining air quality

- Scientifically supported, reliable results

- Provides the documentation required for manufacturers’ warranty compliance

- Vital for determining corrective solutions to protect equipment, processes, and artifacts

- Plus, enjoy the benefits of Purafil's digital coupon portal experience

- Unobtrusive, easy installation and data gathering

- Economical investment for determining air quality

- Scientifically supported, reliable results

- Provides the documentation required for manufacturers’ warranty compliance

- Vital for determining corrective solutions to protect equipment, processes, and artifacts

- Contains a temperature and relative humidity logger for evaluation of controls and limits

- Plus, enjoy the benefits of Purafil's digital coupon portal experience

1 coupon per air vent for critical spaces

View full details

COMMON INSTALLATION SITES

COUPON TESTING PROCESS

HOW IT WORKS

DIAGNOSIS IN REAL-TIME

ACTIVE CORROSION DIAGNOSIS

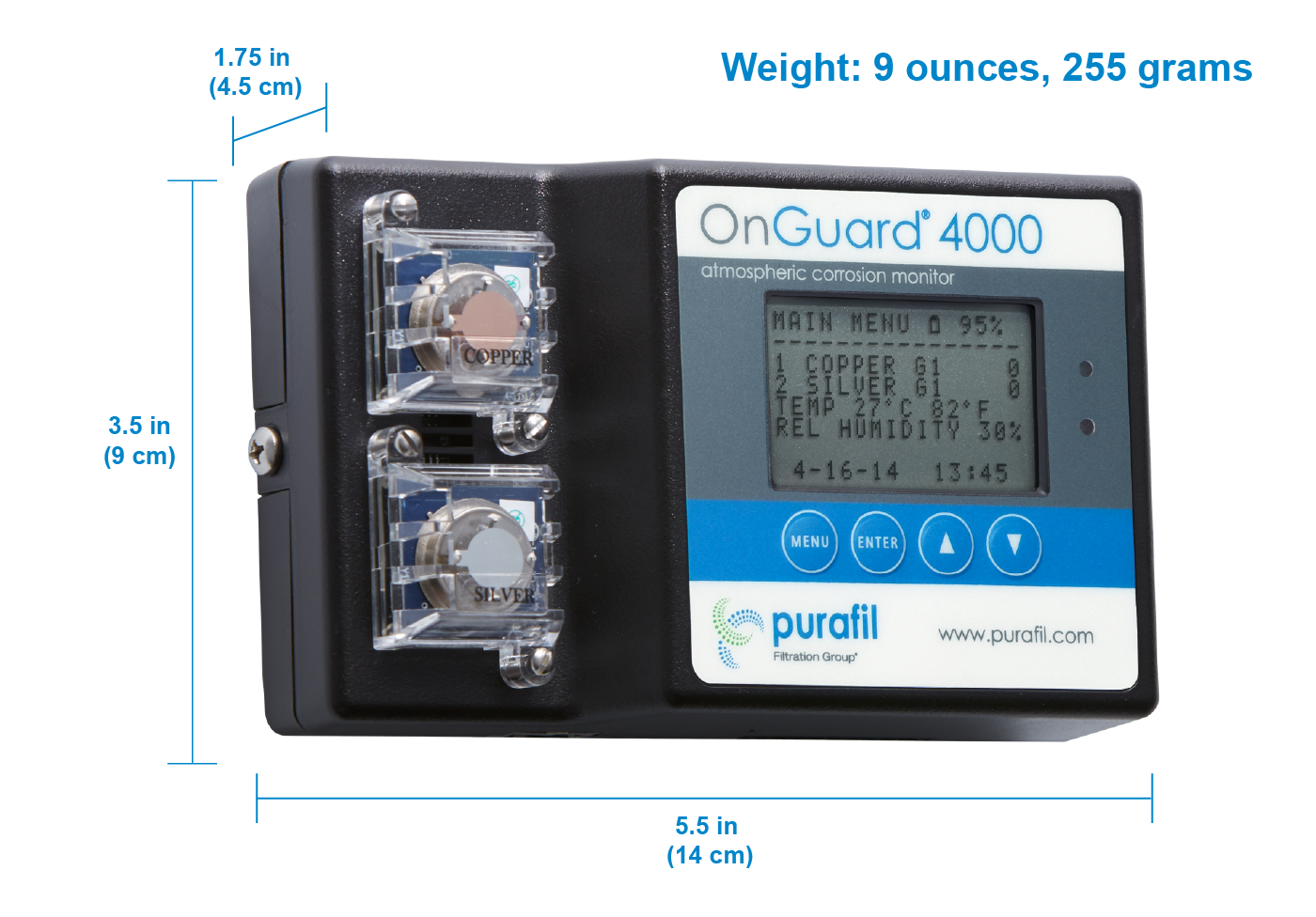

Track the level of corrosion before severe damage occurs, preventing costly downtime and maintenance repairs. The OnGuard measures the overall reactivity level of air in your environment and data is accessible anytime, anywhere.

Measures the Type & Level of:

Corrosion

Temperature

Humidity

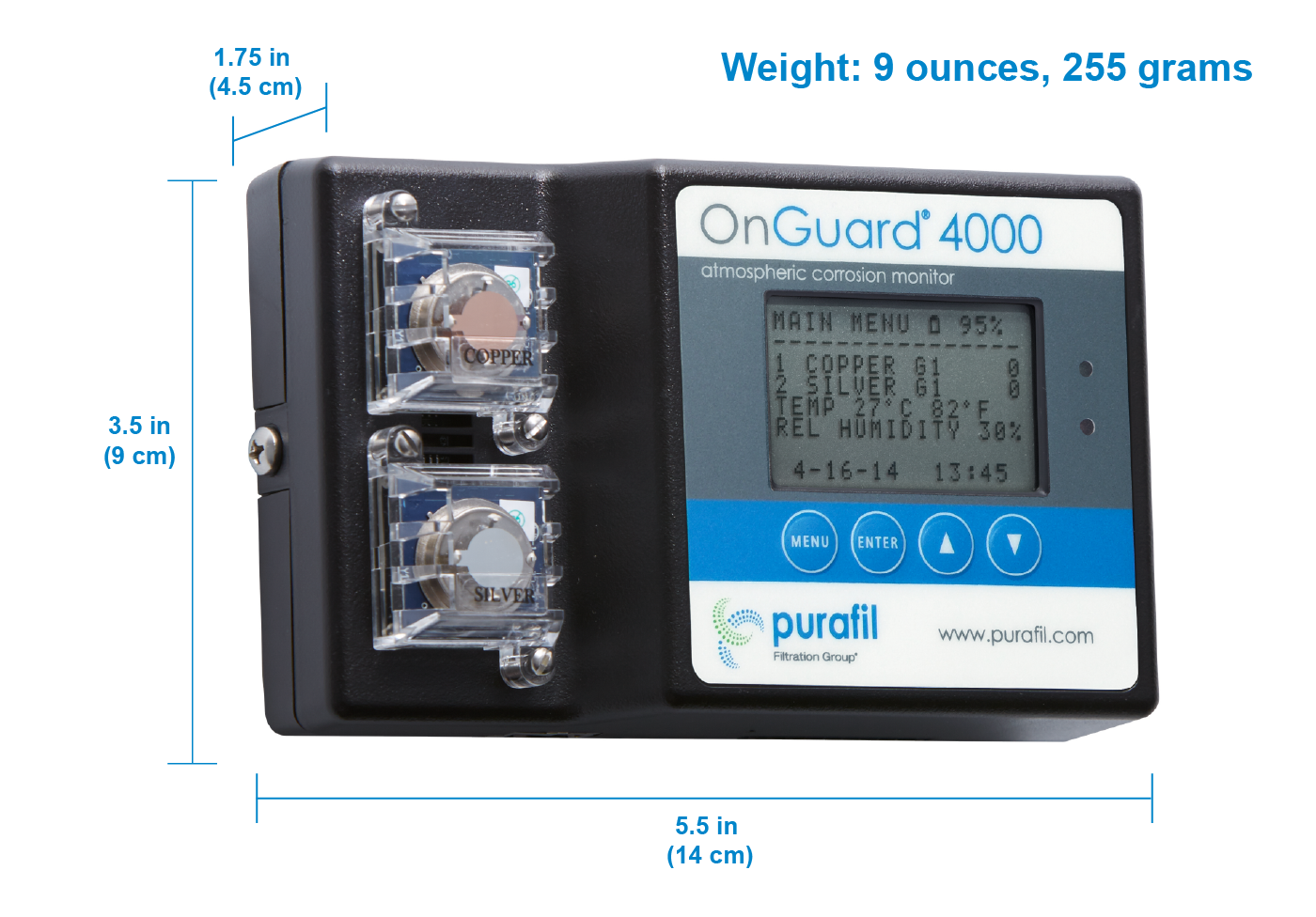

OnGuard 4000

OnGuard Smart

Onguard Copper Replacement Sensor

Onguard Silver Replacement Sensor

- Indicates the level of corrosion before damage occurs, preventing costly repairs/downtime

- Ethernet enabled

- Easy remote access to data and graphs

- RoHS (Lead free directive. Or Restriction of Hazardous Substances Directive) compliant

- Measures corrosion, temperature, & relative humidity on a continuous basis

- Provides incremental and cumulative corrosion data

- Easy to install

- Long service life

- Readings correspond to ISA Standard 71.04-2013

Ships within 2 weeks (Orders of 20 or more will ship within 4 weeks)

Share

ONGUARD MONITORING

HOW IT WORKS

Diagnosis in real time — no 30 day wait or return shipping required.